LSG-6000 Moving Detector Goniophotometer (Mirror Type C) was manufactured by LISUN completely meets LM-79-19, IES LM-80-08, COMMISSION DELEGATED REGULATION (EU) 2019/2015, CIE-121, CIE S025, SASO 2902, IS16106 and EN13032-1 clause 6.1.1.3 type 4 requirements. LSG-6000 is the latest upgraded product of LSG-5000 and LSG-3000 in compliance with the requirements of the LM-79-19 standard Clause 7.3.1, its an automatic light distribution intensity 3D curve testing system for measuring light. The measuring distance is from 5m to 30m.

LSG-6000 gonio photometer manufacturer is LISUN, it can measure all types of lighting sources, LED, Plant Lighting or HID luminaires such as indoor and outdoor luminaires, roadway luminaires, street lamps, flood lights and other kinds of luminaires.

Q1: The equipment has static electricity.

A1: Please connect the ground terminal on the back of the host to the ground separately.

Ground Port

Q2: The power factor displayed in the electrical parameter table is negative.

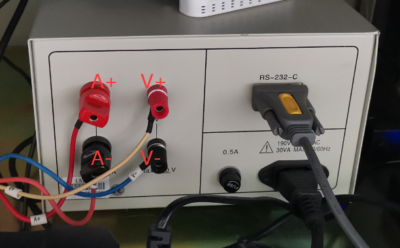

A2: Please exchange and connect the wiring A+ A- on the back of the electrical parameter meter.

A+ A-Switched Connection

Q3: (Trial for use with a DC type electrical parameter meter) Test that the DC voltage is negative.

A3: Switch and connect the wiring V+ V- on the back of the electrical parameter meter.

Q4: The software cannot be opened

A4: It is necessary to plug the key into the USB port of the computer to use the software normally

Plug The Key Into The USB Port Of The Computer

Q5: The standard lamp cannot be lit.

A5: Confirm that the cabinet AC/DC switching switch is at the DC terminal.

Switch At DC Terminal

Check that the standard lamp filament is still intact.

The Filament Is Intact

The standard lamp is a constant current light source. Enter a voltage and current value consistent with the standard lamp certificate. Then turn on.

Consistent Voltage And Current Values

If it still cannot be lit, there is a problem with the wiring. Please check the wiring according to the instruction manual.

Q6: The difference between the calibration distance and the actual distance is relatively large.

A6: After successful calibration, the calibration distance automatically calculated by the software is displayed here

Calibration Distance

The actual distance from the darkroom is the distance from the center of the distribution photometer to the probe. Please refer to the darkroom drawing or actual measurement.

The difference between the two distances should be controlled within 2% or less. If the difference is too large, the following steps may not be well done:

①. The standard lamp is unstable. The standard lamp needs to be lit and stabilized for 15 minutes before it can be calibrated.

②. The darkroom is not painted completely matte black. May leak light or reflect light.

③. Hardware debugging was not adjusted properly. Including host level, probe position and direction, gamma axis zero setting, etc.

④. During calibration, the adjustment of the standard lamp direction was incorrect.

Please check the darkroom and refer to the operating instructions.

Q7: The DC sample lamp cannot be lit.

A7: Please first confirm that the voltage and current of the sample lamp are within the limits of the DC power supply. For example, the maximum output voltage of the DC3005 model DC power supply is 30V, and the maximum output current is 5A.

If the sample requires a constant current power supply (CC), it is necessary to input its rated current value and a sufficiently high voltage.

If the sample requires a constant voltage power supply (CV), it is necessary to input its rated voltage value and input a sufficiently high current.

Q8: The total luminous flux test is inaccurate.

A8: Confirm that the error between the calibration distance and the actual distance is within the normal range. (Refer to Clause 6 above)

If the sample is an asymmetric lamp, such as a street lamp, the angle spacing of ① C (B) should be set as small as possible, such as 5 degrees or 10 degrees. If the sample is a symmetrical lamp, such as an indoor lamp, the C (B) angle interval can be set slightly larger, such as 22.5 degrees and 30 degrees. In any case, the angular interval of ② Gamma (Beta) is 1 degree.

During the C-Gamma test, if the illumination angle of the sample lamp is greater than 180 degrees, the test angle range of ③ Gamma needs to be set to – 180 to 180 degrees.

Angle Range 180 To 180 Degrees

Ensure that the temperature of the darkroom is below 35 degrees.

During the test, please confirm that the sample lamp has turned on and is stable, and that all other lighting in the darkroom is turned off.

Q9: Abnormal light intensity curve shape

A9: Please confirm that the installation direction of the light emitting surface of the lamp is correct. If the direction is skewed, it will definitely lead to abnormal light intensity distribution curves. As shown in the following figure, the light emitting surface of the lamp should be straight downward.

The Lamp Is Directly Downward

If the lamp under test is an asymmetric lamp, there may be different light intensity distribution curves for each C angle of the sample. Different light intensity curves will be obtained when installed on the fixture in different ways.

Fixture Position

Q10: Street lamp test curve abnormality

A10: Street lamps are directional. If the installation direction is incorrect, it may cause some test parameters such as the CU curve of the street lamp to be abnormal. As shown in the following figure, the correct installation direction, C0 direction, and the lamp pole of the street lamp should be oriented towards the direction of the distribution photometer host.

Q11: Device not found when clicking on auto search port

A11: If there are devices in the system, please check whether the device model is selected correctly

If there is no equipment in the system, such as the spectrometer that is not included in the system you purchased, the software will prompt that the spectrometer cannot be connected. Click OK.

Check The System Equipment Model

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *