Product No: JL-8D

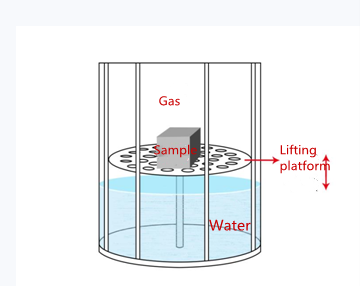

The main function of the IPX8 Visual IPX8 Waterproof Leakage Detector – Air Tightness Testing Equipment is to detect the sealing of products. It achieves the purpose of detecting the sealing of products by fully automatically and accurately controlling the pressure in the test chamber. It has a fully transparent design and can find the leakage point of the sample by checking whether bubbles appear after the sample is immersed in water, so as to facilitate product design, improvement, verification and factory inspection.

Standard:

IEC 60529 (GB/T 4208) “Degrees of Protection Proved By Enclosures (IP Code)”

IEC 60598 (GB 7000.1) “Luminaires – Part 1: General requirements and tests” The requirements of Article 9.2.9.

Application areas: underwater lamps, underwater connectors, underwater sensors, car accessories, waterproof watches, waterproof mobile phone cases and other products for sealing testing.

1. Suitable for the IPX8 waterproof grade test for the product.

2. Three test functions of one device:

(1) water pressure test;

(2) Air pressure test;

(3) Negative pressure test to meet the needs of multiple test methods for samples;

Principle of water pressure testing

(1) Principle of water pressure testing:

• Place the sample on the sample platform in the test tank in advance,

• Cover the lid, lock the screw, set the test pressure and start the device after time.

• The sample platform is immersed in the water with the sample, and the air pressure is increased on the water surface to the set value. If there is a leakage point on the sample, the water will be pressed into the sample. At the same time, the air in the sample will be discharged. Bubble observes the missing point of the sample.

• The test is completed. The sample platform rises out of the water with the sample.

(2) Principles of air pressure testing:

• Place the sample on the sample platform in the test tank in advance.

• Cover the lid, lock the screw, set the test pressure and start the device after time.

• The sample platform is parked in the water surface with the sample, and the air pressure is increased to the set value on the water surface. If there is a leakage point in the sample, the air will be pressed to the inner cavity of the sample.

• After the pressure keeps time, the sample platform is immersed in the water with the sample, and the pressure of the water surface is discharged. At this time, the air pressure in the sample will be discharged. By observing the bubbles, the leakage point of the sample is observed.

• The test is completed. The sample platform rises out of the water with the sample.

(3) Principles of negative pressure testing:

• Place the sample on the sample platform in the test tank in advance.

•. Cover the lid, lock the screw, set the test pressure and start the device after time.

• The sample platform is immersed in the water with the sample. When the water surface is vacuum to the set value, the sample will be pressed. If there is a leakage point on the sample, the air in the sample will be pulled out of the vacuum. You can observe the leakage point of the sample through bubbles.

• The test is completed. The sample platform rises out of the water with the sample.

• The tank body uses acrylic material and is all transparent around (convenient to observe the test sample testing situation),

• Special silicone sealing ring, good elasticity, not easy to damage, the service life is up to 10 years.

• The pressure tank has been 2 times the pressure resistance test in the factory. It is installed with a large brand “Super” brand safety valve to ensure the safety of users.

• Control system: Use a 7 -inch color touch screen; the touch screen can be set on the touch screen: pressure -reducing time, test pressure, delay pressure leakage time and other parameters, full touch operations, easy to use.

• Electric control elements adopt imported brands (such as: LS, Omron, etc.); pneumatic elements use Taiwan’s original Adeke to ensure the stability and service life of the equipment.

• Pressure control: use 0.5 high -precision pressure sensor, water depth control accuracy ± 20cm.

Technical Specification:

| Structural parameters | |

| Outer Size | About 800*550*1000mm(L*W*H) |

| Inner Size | About diameter350*400mm(height) |

| Tank Thickness | 15mm |

| Tank Material | Acrylic |

| Flange Thickness | 20mm |

| Flange Material | Stainless steel |

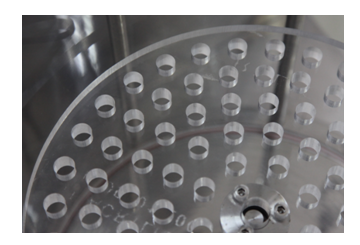

| Sample Tray Size | Diameter 330mm |

| The height of the tray from the bottom | 195mm |

| Weight | About 80KGS |

| Function Parameter | |

| Pressure control method | Automatic adjustment |

| Pressure error | ± 0.2 m/±0.002 MPa |

| Test water depth range | 1-10m |

| Pressure adjustment range | Negative voltage range: -0.05-0MPa; Positive pressure range: 0.01-0.1MPa |

| Safety valve exhaust pressure | 0.15Mpa |

| Test Time | 0-999999 S |

| Protective Device | Protection of mechanical safety valve, leakage switch protection |

| Electrical Parameter | |

| Voltage | 220V |

| Power | 100W |

Working Condition:

| Working Place | • Flat ground, ground load -bearing capacity is not less than 200kg/㎡; • The venue is well ventilated; • There is no strong vibration around the equipment; • Non -flammable, explosive, corrosive substances and dust around the equipment; • There is appropriate use and maintenance space around the equipment; • The back of the device, the left and right sides, the top: 600mm; the front side of the device: 1000mm. |

| Environmental Conditions | Temperature: 5 ℃ ~ 35 ℃ Relative humidity: ≤85% Bad pressure: 86kPa ~ 106kPa |

| Water Source | Tap water/pure water, DN15 faucet |

| Drainage Condition | Install a DN15 drain pipe |

| Air Source | If the user has the air compressor, it is recommended to output air pressure: 0.6MPa -0.8MPa. Install fast connector |

Transparent tank

Sample tray