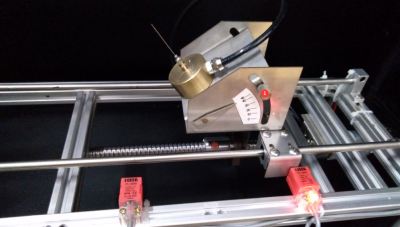

The needle flame tester is applicable to the research, production and quality inspection departments of electronic equipment and its parts and components, such as lighting, low-voltage appliances, household appliances, machine tool appliances, motors, electric tools, electronic instruments, electrical instruments, information technology equipment, electrical affairs equipment, electrical connectors, accessories, etc., as well as the industries of insulating materials, engineering plastics or other solid combustible materials. Its design complies with the requirements of GB/T5169.5-2008 “Fire Hazard Testing for Electrical and Electronic Products – Part 5: Flame Needle Flame Test Methods, Devices, Confirmation Test Methods and Guidelines” and other standards. It has the characteristics of reasonable structure, precise control, and simple operation.

Needle

Functional features:

1. Programmable controller touch screen+PLC control, achieving multifunctional control/detection/calculation/data display

2. High degree of automation: automatic recording of test time, automatic display of test results, automatic timing, automatic ignition, automatic return of Bunsen burner after the completion of flame application, and whether to turn off the gas can be selected

3. Adjustable automatic ignition time during startup

4. Start testing, reset, ignition, calibration, setting, lighting, and exhaust are all controlled through the touch screen, and the test can be completed by lightly touching the fingertips

5. The timing button is used in conjunction with the PLC to automatically record and store the combustion time consumed

6. Automatic recording of test time system

Preparation for needle flame test:

1. Place the test sample, white pine wood board, and silk paper in an atmospheric environment with a temperature of 15 ℃ -35 ℃ and a relative humidity of 45% -75% for 24 hours.

2. Check whether the equipment and instruments meet the testing requirements of this project.

3. Before the experiment, prepare sample data (material composition, sample structure diagram, etc.), fire hazard analysis of the sample, and testing records.

4. Fill in the inspection record with the status of the prototype, the identification content of the prototype, and relevant technical parameters.

Flame retardant standard:

IEC60695-2-2, GB5169.5-97, GB4706.1

Corresponding standards for ZY-2 needle flame testing machine

GB 4706.1-1992 “General Requirements for Safety of Household and Similar Electrical Appliances”

GB4706.2-2003 “General Requirements for Safety of Household and Similar Electrical Appliances”

What is the flame test steps:

1. Turn on the power switch of the combustion chamber and set the test time and observation time to 30 seconds.

2. Open the combustion test door. Turn the gas switch back to the “OFF” position and confirm that the cylinder button is in the “disengaged” position. Due to special safety design, if the gas switch is not turned to the “OFF” position, the gas cylinder will not be able to be loaded into the furnace body.

3. When placing gas cylinders, the gap of the cylinder valve must be facing upwards. It is necessary to pay attention to the connection between the gap of the gas cylinder valve and the protruding part of the pressure sensing safety device of the portable furnace.

4. Press the gas button to the “SET” position. If the gas cylinder is installed incorrectly, it can cause butane gas to leak and emit a “sizzling” sound. When installing gas cylinders, it is necessary to check them clearly and make no noise.

5. Press the flame adjustment button on the control panel, and the device will open the solenoid valve and automatically ignite. If the burner does not catch fire, immediately click the stop button, and adjust the gas flow meter appropriately. Press the flame adjustment button again. The accessories are equipped with duckbill gauges, and other measuring tools (such as Vernier scale) can also be used to adjust the gas flowmeter again to stabilize the flame height at 12 ± 1mm; The needle flame test temperature increased from 100 ℃± 5 ℃ to 700 ℃± 3 ℃, and the test time was 23.5 ± 1.0 seconds.

6. Press the debugging button, and the burner car will stop at the right limit position. Adjust the burner to form a 45 ° angle with the horizontal plane, adjust the burner and fixture to make the distance between the burner and the bottom surface of the sample 8mm or 5mm from the side. Turn the left or right up/down self reset switch to adjust the test sample carrier that has already been clamped on the right to the standard position.

7. Wrap a layer of silk paper tightly on a smooth white pine board with a thickness of about 10mm and place it 200 ± 5mm below the position of the test sample where the needle flame is applied.

8. After the flame temperature reaches, activate the test switch to observe the test sample, the parts around the test sample, and the underlying layer, and record the combustion duration (t) from the moment the test flame moves away until the flame extinguishes, or until the test sample, the parts near it, or the underlying layer used for the test is no longer scorching.

9. Press the reset button, and the burner trolley will return to the initial position on the left.

Test results:

According to the product standard requirements, if there are no requirements in the product standard, meeting one of the following requirements is considered qualified:

1) The test sample does not produce flames or scorching phenomena, and the packaging paper does not ignite or the white pine board does not carbonize.

2) After removing the needle flame, the flame or scorching duration of the test sample, surrounding parts, and bedding layer is less than 30 seconds. The parts and bedding layer around the test sample will no longer continue to burn, the packaging paper will not ignite, and the white pine board will not carbonize.

Precautions for needle flame tester:

1. After the test is completed, turn out some of the gas manual control knobs. If the gas cylinder is not disassembled correctly, it will cause butane gas leakage and make a “sizzling” sound.

2. Turn on the fan to exhaust exhaust exhaust gas and smoke, turn off the flow meter, and then turn out the knob of the gas cylinder device to separate the gas cylinder

3. The duration of the flame cannot be recorded, it is likely due to forgetting to press the “pause” button.

4. Pay attention to keeping the combustion chamber clean, especially at the needle tip, to avoid blockage; After each test, clean the combustion chamber in a power off state.

5. Both the fan and lighting are controlled on and off by independent buttons.

6. Warm thermocouple is a vulnerable component, please be careful when using it, it is not included in the product warranty.

According to IEC60695-2-2, IEC60695-11-5 and GB/T-5169.5, ZY-3/ZY-3S needle flame test equipment is applied in the production and quality control department of lighting products, hyperpiesia electrical apparatus, domestic appliance, machine electric appliance, electrical machine, power tool, electronic instrument, electrician instrument and technical equipment. Also, the apparatus is fit for the industry of insulation material, engineering plastics and solid combustible material.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *