Product No: LS60745-F103

The no-load life and durability test bench of the electric hammer is in accordance with the standard requirements of Figure 103 of IEC 60745-2-6. The electric hammer or electric drill is loaded to make it run intermittently. Test whether the electrical and mechanical hazards that may be generated by the electric hammer or electric drill under normal use meet the standard requirements.

The equipment is composed as follows:

1. The electrical control cabinet contains Mitsubishi PLC, 7-inch touch screen, control panel, load (voltage 0-250V adjustable, voltage and current display);

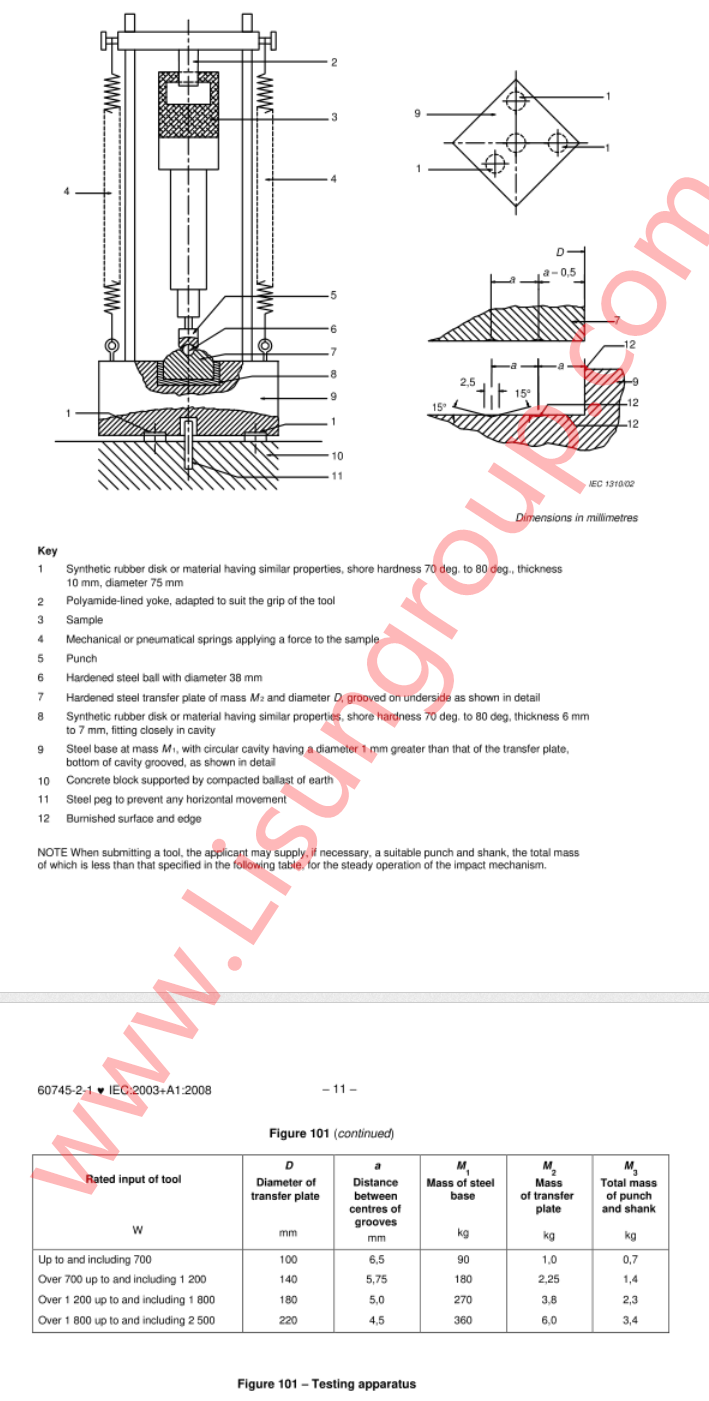

2. The mechanical device is shown in Figure 103 and above. Includes a 360kg steel base, an impact head, steel pads and clamps.

Standard:

IEC 60745-2-1 “Hand-held motor-operated electric tools – Safety – Part 2-1: Particular requirements for drills and impact drills” Figure 101

IEC 60745-2-6 “Hand-held motor-operated electric tools – Safety – Part 2-6: Particular requirements for hammers” Article 17 Figure 103

GB 3883.6-2012 Figure 101

GB 3881.7-2012 Figure 103

IEC 60745-2-1 Figure 101

Application:

Conduct durability tests on handheld power tools below 2.5kW.

Sample range:

Electric drill, impact drill and electric hammer.

Specification:

1. No-load operation test: All electric hammers, including hammer drills, are installed on the test device shown in Figure 103. The hammer drill is away from the electric hammer mechanism and runs at 1.1 times the voltage. It runs for 12 hours without load and then runs for 12 hours at 0.9 times the rated voltage. Each operation cycle consists of 100s continuous operation and 20s power-off rest. During the test, the electric hammer is placed in three different directions (horizontal, vertical upward, and vertical downward) at each voltage, and each position runs for about 4 hours.

2. Load operation test: All electric hammers, including hammer drills, are installed on the test device shown in Figure 103. They run for 4*6h each time at the rated voltage or the average value of the rated voltage range, with at least 30min intervals each time.

In these tests, the electric hammer is in the power-off operation state, and each operation cycle consists of a 30s connection operation cycle and a 90s power-off decomposition cycle. During the test, the elastic body applies axial force for the stable operation of the impact mechanism.

Switches not installed on the tool can be connected or disconnected. During the test, it is permitted to use brushes and add tool and lubricant oil to the tool. If the impact mechanism fails mechanically during the test but does not cause partial power failure, it is permitted to use a new impact mechanism.

| Test Requirement | Technical Specification |

| Power supply | 220V/50Hz (120V/60Hz is option) |

| Air required | 5~8 bar |

| Electrical control | Mitsubishi PLC operation, 7 -inch touch screen operation |

| Load voltage | 0-250V adjustable, the current can be displayed |

| No load rotation angle | 0°,90°,180°,Can manually reverse |

| No load rotation speed | 0-360°/s, can be set |

| Connection time | 0-999.9s, can be set |

| Power off | 0-999.9s, can be set |

| Test time | 0-9999h, can be set |

| Total test time | 0-9999h, can be set |

| Interval time | 0-9999min, can be set |

| Load pressure | 100, 125, 150, 175, 200, 250, 300, 350, 400N, can be set |

| Impact head | 0.7, 1.4, 2.3, 3.4kg (Including the quality of the connector), follow datasheet 101 to use it |

| Steel ball | Φ38mm |

| Steel pad | 100, 140, 180, 220mm, follow datasheet 101 to use it |

| Rubber plate | A set of 4, matching the steel pads and steel base |

| Steel base | Weighing 90KGS, equipped with 9 pieces of 30KGS coding |

| Size and weighing | Electric cabinet 60*40*75cm, weighing about 100kgs; Rack 40*40*200cm weighs: 390kgs |