Determination of accessible parts

Accessible parts of equipment

General

An accessible part of an equipment is a part that can be touched by a body part. For the purposes of determining an accessible part, a body part is represented by one or more of the specified test probes.

Accessible parts of an equipment may include parts behind a door, panel, removable cover, etc. that can be opened without the use of a tool.

Accessible parts do not include those that become accessible when floor standing equipment having a mass exceeding 40 kg is tilted.

For equipment intended for building-in or rack-mounting, or for subassemblies and the like for incorporation in larger equipment,accessible parts do not include those that are not accessible when the equipment or subassembly is installed according to the method of mounting or installation specified in the installation instructions.

A part is considered accessible if the instructions or markings intended to be followed require that a person physically contacts that part. This applies without test and irrespective of whether a tool is required to gain access.

Test method 1 – Surfaces and openings tested with jointed test probes

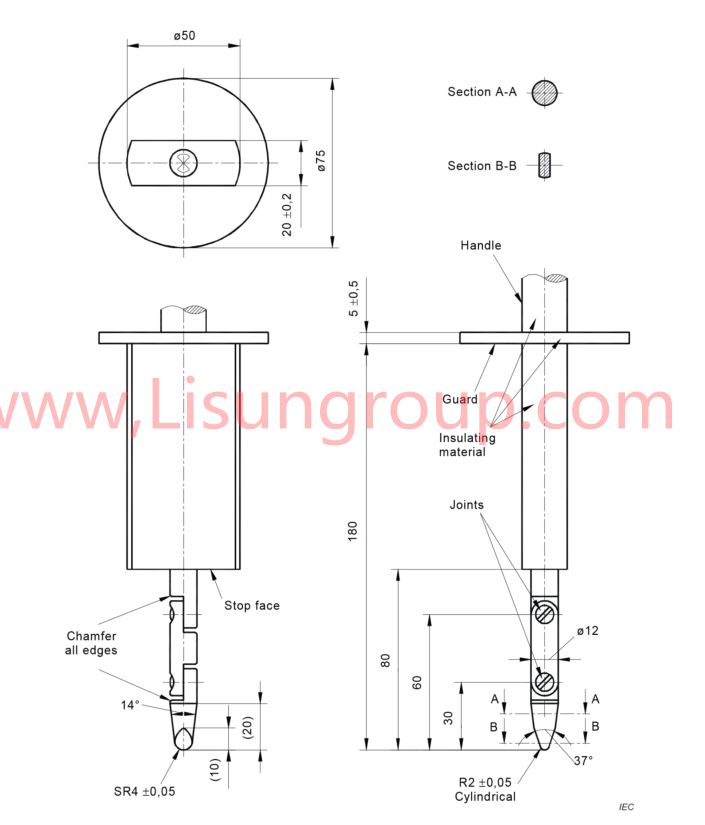

For surfaces and openings, the following jointed test probe is applied, without appreciable force and in any possible position, to the surfaces and openings of the equipment:

– the test probe of Figure V.1 for equipment that is likely to be accessible to children;

NOTE 1 Equipment intended for use in homes, schools, public and similar locations is equipment generally considered to be accessible to children, see also Clause F.4.

– the test probe of Figure V.2 for equipment that is not likely to be accessible to children.

IEC 62368-1 UL Unjointed Finger Probe

Where entry behind a door, panel, removable cover, etc. is possible without the use of a tool, or entry is directed by manufacturer instructions or marking, with or without the use of a tool, the test probe is applied to surfaces and openings in those areas.

Where the entire probe passes through a large opening (allowing entry of an arm but not of a shoulder), the probe shall be applied to all parts within a hemisphere with radius of 762 mm. The probe handle shall point along a path towards the large opening to simulate the hand on the end of the arm extending through the large opening. The plane of the hemisphere shall be the outside plane of the opening. Any part outside the 762 mm radius hemisphere is deemed not accessible.

NOTE 2 The equipment can be dismantled to perform this test.

Test method 2- Openings tested with straight unjointed finger probes

Openings preventing access to a part by the applicable jointed test probe of Figure V.1 or Figure V.2 are further tested by means of a straight unjointed version of the respective test probe applied with a force of 30 N. If the unjointed probe enters the openings, test method 1 is repeated, except that the applicable jointed version of the test probe is pushed through the

opening using any necessary force up to 30 N.

SMT UZ11 Figure V.2

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Tags:SMT-UZ11

Your email address will not be published. Required fields are marked *