Abstract

The improvement and spreading of the LED filaments lamps requires reliable and accurate methods and instruments for junction temperature measurement. Based on the forward voltage methods, the measurement process and the equipment of LED filaments lamps are introduced. And the dependence of junction temperature on various factors are discussed.

General

Though the LED filament lamp technology has been mature for applications in recent years, it still face some difficulties in thermal management that will lead to rapid light degradation and low lamp power, and limit the application exploring and the market expending.

The junction temperature Tj of LEDs is the key to determine the luminaire performances especially the luminous maintenance and lifetime. The reliable and accurate methods and instruments of Tj measurement are required for LED filament lamps, not only to objectively evaluate the rationality of thermal design, but also to improve the system design and manufacture technicals for the sake of enhanced productivity as well as extended rated lifetime.

The LED filaments are sealed in the glass bulb filled with gases, only leaving two polarity leads outside to connect to the driver. Since it is hard to inject thermocouples into the sealed bulb or make the infrared light transmit the glass, the pin temperature and thermography methods can’t be applied for filament lamps. Forward voltage method is the right choice.

Forward voltage method for junction temperature measurement

The voltage method used for Tj measurement of semiconductors, was issued by Joint Electron Device Engineering Council (JEDEC). The Tj is derived from the transient forward voltage of LEDs at the certain test current when operating, based on temperature characteristic of PN junction.

At the constant current, the junction voltage keeps the approximate linear relation to temperature for most semiconductors, which represents that the voltage decreases monochromatically with increased temperature. For this reason, the junction voltage VF is firstly tested under multiple setting temperatures at the small calibration current IM, so as to calculate the coefficient K which represents the relation between voltage and temperature in unit [mV/℃]. During the calibration, the tested LED is put in the thermostat container to keep constant temperature. Then the LED is driven at the rated current IF to keep stable operation. The rapid switch is conducted from rated current IF to calibration value IM, and the transient voltage VF is measured on the thermal equilibrium state. Consequently, the Tj of the LED can be derived through the voltage-temperature curve by PC programme.

Considering that LED luminaire is the system integration including semiconductors, mechanical components, optical elements as well as drivers, the thermal characters of each part may have influence on the overall performances of the product. Especially for integral luminaire, the compact design results in the thermal interactions between LED and driver dependent on the thermal design and installation form. Therefore, the Tj of LED luminaire should be evaluated by the whole system instead of the simple LED chips.

The filament is composed of multiple LED chips in series, connected to each other either in series or in parallel. All the filaments are sealed in the lamp bulb, so that they have to be measured as a whole. For the standard product, the LED bulb and the driver should be separated, leaving two couples of polarity leads to connect to LISUN TRS-1000 Thermal Resistance Spectroradiometeric System for LED. It full meet the LM-80 standard. A thermocouple is also connected, adhering to any position on the bulb surface.

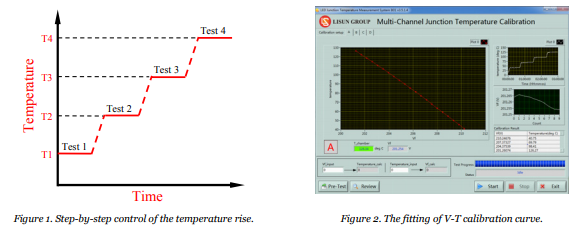

The filament LED bulb is put into the thermostat container and then the voltage-temperature curve can be calibrated when the temperature rise step by step, as shown in Figure 1.For each step temperature Tn, the corresponding voltage VFn is calibrated until the temperature in container rises to the setting value and meanwhile the LED filament reaches thermal equilibrium. The stable period is suggested to be automatically determined by LISUN TRS-1000. The calibration current IM is settled according to the parameters of the test lamp, and keeps constant for various Tn. Hence the V-T curve can be fitted, as displayed in Figure 2. After calibration, the test bulb was removed from the container and recovered to the original structure with two couples of leads connected as mentioned above. The VF is recorded at regular intervals from the ignition to the equilibrium, which is used to derive the sequential curve of the Tj. The LED luminaire should be keep into the windshield or in the environment without air convection.

The Tj curve of an example is illustrated in Figure 3. The measurement was conducted at ambient temperature 29 ℃ with no wind indoor. After the bulb was turned on, the LED Tj increased and reached stable at 121.3 ℃ during the first stage. Then at the second stage, the exhaust was manually damaged to make the air exchange between the bulb and the atmosphere. The Tj gradually increased until the new equilibrium at 159.5 ℃. The reference temperature tested by thermocouple on the bulb surface was kept at 40.8 ℃ under normal operation, and raised to 46.3 ℃ on leak state. The great increase of Tj after air leaking represents the significant effects of filled gases on heat dissipation. And the change of bulb surface temperature has no relation to the Tj of the LED filaments.

The driver output also has direct effect on the Tj, as displayed in Figure 4. At ambient temperature of 28.3 ℃, the input voltage of the LED filament lamp was adjusted in the range of 220±10% to simulate the mains voltage fluctuation. The Tj are 106.6 ℃, 121.7 ℃ and 137.9 ℃ separately at voltage of 198 V, 220 V and 242 V.

Reference:

[1] JEDEC Standard EIA/JESD51-1. Integrated Circuits Thermal Measurement Method—Electrical Test Method (Single Semi- conductor Device) [S], 1995.

[2] Xi Y, Schubert E F. Junction–temperature measurement in GaN ultraviolet light-emitting diodes using diode forward voltage method [J]. Applied Physics Letters, 2004, 85 (12): 2163−2165.

[3] CALT 001-2014, Measurement method of junction temperature for LED in luminaire [S].

[4] Chen X Y, Zhang X G, Yang Y L, et al. Junction temperature measurement with forward voltage method for LED luminaire [C]// The Proceeding of 2015 China LED Lighting Forum. Shanghai, 2015. 238−241

Your email address will not be published. Required fields are marked *