ESD tables are excellent if you restrict and regulate the quantity of electricity in a certain region. ESD means electrostatic discharge and is the consequence of static accumulation between two items. Electrostatic charge accumulation often happens when two distinct kinds of materials rub together. One item will be charged positive, while the other is charged negatively, which will eventually lead to an ESD test if the object is not correctly grounded.

ESD equipment is essential for avoiding ESD occurrences since it may harm electronic components. The ESD solution will have a static control laminate, and some machinery may also be designed to be chemically and scratch-resistant. ESD Laminate is one of the finest surface materials you may utilize in your workplace when static sensitivity is a significant problem.

A variety of methods may minimize static electricity, including the kind of surface you put in your workstation. In particular, ESD laminates are suitable for situations where components and materials are static sensitive and need protection.

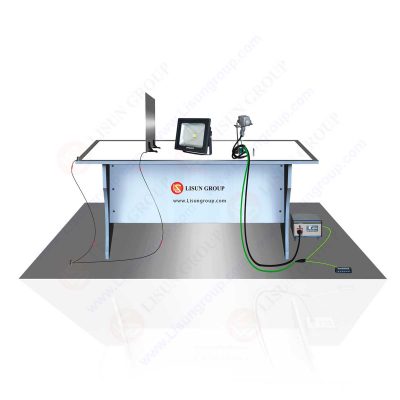

ESD Standard DESK

STATIC SURFACE DISSIPATIVE

The resistance value of an ESD protection surface should typically be between 1.0 x 109 and 1.0 x 106 ohm. This is for two purposes: first, to avoid a quick release of any static that may cause harm, and second, to prevent the safety mentioned above concerns. The surface of the bench is the key to the functioning of the ESD table.

What is the Detail ESD desk work surface?

Since static may be built on a working bench anyplace, all working surfaces of the bench must be static dissipating. The racks must be part of the ESD-protected area. Either you may put electronic assembly or instruments here. Furthermore, if instruments are put on the non-ESD waste surface, attract static, and are utilized to operate an electronic assembly, damage possibilities increase.

TOP TABLE

The top of the table is the work area on a workbench most often utilized. And the majority of ESD tables are used for soldering; then, the static dissipating and the fireproof workbenches are requested.

Other work surfaces:

The ESD workstation comprises some of the following elements

Shelves:

Shelves are often used for electronic assembly, repair, and inspection of replacement components and other devices. Detail ESD Shelves are equipped with two types of materials. First, we call the metal shelves, and second, like the tabletop, ESD lamination, we call the material. LISUN has the best esd tables for the esd test.

Metalwork:

Although the metalworking itself is conductive, the paint used is usually not conducive. For an ESD workbench, static dissipative paint must be used to avoid abrupt discharge. Moreover, since this painting is the key component of an ESD table, the most precious items should be utilized for a very long period for cost-effectiveness. To prevent scratching, the detail utilizes the unique ESD powder coating with an average 1,0 x 106 <1,0 x 109 ohms resistance.

ESD WORKBENCH CHARACTERISTICS:

1. Durable Material: Strong cold steel with a powder coating ESD anti-scratch. ESD workpiece lamination (fireproof).

2. Ergonomic design: attractive and pleasant, improving productivity efficiency

3. Modular design: different accessories may be combined

4. Standard model: exchangeable accessories, greater cost efficiency to replace broken components.

5. Permanent ESD feature: ESD powder coating and ESD laminate top are permanently valid.

CONCLUSION:

The use of a suitable ESD table is the requirement of the day, and in that regard, there should be no compromise. For this purpose, Detail ESD Workbench’s services are excellent since they match the needs of the contemporary world and are accessible at fair and, therefore, affordable prices.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dept: Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

Your email address will not be published. Required fields are marked *