Surges are a nightmare for any circuit designer and a very important aspect of electronics. These spikes are frequently referred to as “impulses,” which are high voltages that last for a brief period of time and are typically measured in the kV range. Lightning is an example of a natural phenomenon that creates surges. Surges are characterized by a high or low fall time in voltage followed by a very rapid rising time.

It is crucial to assess our gadgets’ ability to withstand surges because this surge has the potential to seriously harm electrical equipment. Here, we employ a surge generator to produce high voltage or current surges under carefully regulated testing conditions. We shall learn about the LISUN Surge Generator’s operation and use in this article.

Input surge testing is one of the main immunity tests that electrical and electronic equipment is put through. The limitations for this test are established by the requirements for the end system, and the test method is IEC61000-4-5. The test basically involves adding voltage spikes on top of the system’s nominal voltage input.

These spikes are a good representation of voltage changes brought on by things like heavy motor drives, lightning strikes nearby, etc. When applied to a system that is not equipped to handle them, these large voltage variations can result in a number of problems. Testing guarantees that the finished product will perform at the level required for the intended use.

In some applications, it might be appropriate for a system to crash following a surge incident, requiring the user to manually reset the device. That is not permitted in other, more mission-critical systems. Throughout the entire event, the system must function without any faults. Performance criteria are used to assess how the system will react to the deployment of the surge.

Surge Generator SG61000-5

The Installation Class that is called out for the end system determines the test levels that are applied during the test. The majority of commercially available power supplies have been independently tested to Installation Class 3, which requires 1kV surges between the line and neutral and 2kV surges between the line and ground. In order to respond to the application of the surge, an end system must perform at a certain level according to the performance criteria.

They receive a plain A, B, or C grade. According to Performance Criteria A, the system is unchanged as a result of the test. The system does alter during the test, but it automatically recovers after the surge occurrence, according to Performance Criteria B. Finally, Performance Criteria C requires that the user make a post-event intervention with the system in some way. This could entail doing anything from restarting the system to clearing an error code. Failure would occur if the surge caused damage to the system.

It is extremely simple to identify whether the performance criteria for an end product are A, B, or C. Determining critical performance for a power supply tested in isolation is a little trickier. IEC61000-4-5 describes the voltage spike’s generation, when it happens, how frequently it happens, and how long it lasts in between.

But the device or equipment producer is in charge of choosing the performance criterion (A, B, or C). The power supply business has long relied on the practice of measuring the output using a standard moving coil or digital voltmeter, checking the output to see whether it deviates during and after the test, in combination with the approved test facilities.

Since the beginning of the standard, this approach has been normal, and in the vast majority of circumstances, it is sufficient to determine vital performance, demonstrating that the power supply has continued to function without interruption to the DC output. Sometimes problems occur when the final apparatus is delicate to brief voltage variations or ground disturbances.

Such brief disturbances might arise and go undetected by a normal voltmeter because of the power supply’s input to output capacitance. An oscilloscope must be used to see these disturbances, which is difficult in and of itself because the surge voltages are large and have enough energy to produce radiated disturbances and ground disturbances that are seen at the oscilloscope.

Inadequate measurement setups lead to inaccurate conclusions about the supply’s performance, hence extreme caution must be used when connecting the oscilloscope probe to the system & measuring grounding in order to obtain an accurate result.

Since no other test can detect turn-to-turn insulation deficiencies, surge tests are crucial. These flaws, which are precursors to severe failures and motor shutdown, begin at voltages higher than the motor’s working voltage. Surge tests are also used to identify hard shorts and several other errors in coils and windings. Three almost exact waves from a three-phase motor.

Most winding failures, including shorts to ground, originate with inadequate turn-to-turn insulation. Once the vulnerability creates turn-to-turn arcs, an electrical closed loop is produced. Current begins flowing through the loop as a result of transformer activity. A hotspot is produced when this current dissipates as heat. The hotspot causes additional turns to short out, which produces more heat. The winding shorts eventually reach the earth.

Since the results of one coil or phase are compared to those of another, surge tests are also referred to as surge comparison tests. Since coils are made to be comparable, the results of the surge test ought to be roughly equal. Operators utilize the pulse-to-pulse surge test when phases are not identical or when there is nothing to compare to.

Fast rising pulses are sent via the coil or motor in succession. Based on industry standards and best practices, the operator determines the voltage of the surge test pulses. The test voltage is between the motor’s max operational voltage and approximately 3.5 times that value. The most typical formula is 2E+1000V, where E is the motor’s operating RMS voltage.

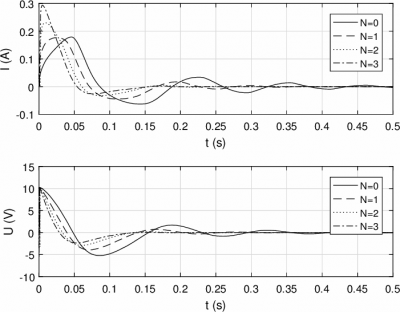

These are surge test waveforms that are created during the surge tests.

By using the oscilloscope channel in the tester, the surge pulses create a fading wave shape. Every wave is contrasted with waves from other coils or from different motor phases. The touch screen displays all waveforms. If the coils or windings are same, the waves are almost identical. The wave will have a different frequency from the others and look separate if one has a flaw or insulation failure.

When the tolerance for pass/fail is uncertain but there are natural variations in the surge waves, the pulse-to-pulse surge test is used. This is the case for many concentric wound stators and certain built motors. When there are no comparable coils or phases, it is also employed.

With the help of the surge comparison test, coils, windings, electric motors, generators, alternators, and transformers can all be found to have insulation problems and shorts. Usually, turn-to-turn, coil-to-coil, or phase-to-phase faults are involved. For DC motors, the surge comparison test also uncovered issues with incorrect internal connections, incorrect turn counts, and more.

Most winding failures are caused by poor turn-to-turn insulation. Due to the fact that it is the only test that can identify inadequate insulation, the surge comparison test is crucial for motor dependability and maintenance plans. The surge comparison test is a crucial quality control technique for coil and motor manufacturers and is especially effective when used in conjunction with partial discharge measurements.

Any sort of coil can be tested, including the largest electric motors and generators as well as tiny sensors, antennas, and actuating coils in relays or solenoids. Operators must take test voltage standards into consideration because the surge test is a load-dependent test.

The only test that can detect weak turn-to-turn insulation is a surge test. This is a result of surge tests using higher voltages. Low voltage testing do not put the insulation under stress, hence there are no dielectric flaws observed. The only test that can detect weak phase-to-phase and coil-to-coil insulation is a surge test. When it is not feasible to HIPOT test each coil and phase individually against the other coils and phases, a HIPOT test may be utilized.

Finally, a surge test is the only way to discover some connection issues. Sometimes, but only when the resistance is accurate, an inductance test is employed.

Surge comparison testing don’t harm anything. Most frequently, they are carried out at a voltage that is higher than the motor’s peak working voltage but significantly lower than the insulation’s design voltage. A low amount of energy is consequently used in an arc. A nice illustration is the arc that results from static electricity from your finger to a door handle. The voltage ranges from 12 kV to 20 kV, but since the energy is so low, it is safe.

As long as the number of pulses utilized in the surge comparison test is kept to a minimum and the test is conducted when over-voltage tests are advised, a low-energy arc generated by a surge test won’t harm the insulation in a winding.

Utilizing surge voltage generators, high and low resistance defects in power lines can be pre-located as well as pinpointed. The defective cable receives intermittent feeds of the high voltage capacitors’ stored energy. An acoustic noise is produced at the location of the defect from this, and a ground microphone can pick it up.

A synchronous generator made for short-duration operation in short-circuit situations, typically for three-phase current.

A two-pole turbine generator with air cooling is typically used as a surge generator. These generators are used to test the switching ability, thermal stability, and electrodynamics stability of high-voltage equipment. The testing device is either directly or indirectly connected to the surge generator by a transformer.

The surge generator is cooled for several minutes following the brief circuit, which lasts for 0.06-0.15 seconds. The power ratings of the greatest surge generators range from 3 to 7.5 gigavolt-amperes; the voltage generated typically ranges from 6 to 20 kilovolts (kV). Asynchronous electric motors with phase-wound rotors that have a power rating of up to 6 gigawatts and are excited by a different source power surge generators. The significant electrodynamics pressures (surge stresses) that short-circuit circumstances place on the stator winding are what make surge generator design and construction challenging.

The surge test should be executed appropriately and with a test interval of 60 seconds, which should be checked and verified first. Due to the length of the entire test, the standard does allow you to shorten the time between surge applications.

The 60s period should be used, leaving enough time for discharge between surges, if a system fails the test at reduced intervals.

When a single unit is tested repeatedly, it degrades specific supply-side components, which are stressed during a surge test. For instance, this is true for MOVs. Repeatedly testing a system with the same power supply could eventually result in performance degradation.

A capacitor connected across the DC supply near to the load connection point frequently fixes the problem by very efficiently offering a low impedance at the crucial connection point if the end equipment is impacted by brief disturbances on the DC supply or ground plane. This might lessen the severity of any disruptions that are observed in the system’s voltage.

A ferrite on the earth ground wire with two to three turns through it as close to the system’s AC input may be helpful if the system has an earth ground connection. As a result, the supply will not be under as much stress from the surge voltage. This strategy has shown positive outcomes in delicate applications. Finally, the system’s power cable routing is a frequent cause of problems. It is advisable to keep sensitive low voltage electronics well away from AC input cable and DC cabling.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com , Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com , Cell/WhatsApp:+8618117273997

Tags:SG61000-5

Your email address will not be published. Required fields are marked *