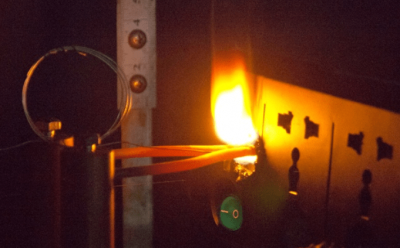

The glow wire test is a physical experiment. The purpose is to test the stability of electronic and electrical products at work. The glow-wire tester heats the heating wire of the specified material (¢4 Ni80/Cr20) and shape with a large current to the test temperature (550 ℃ ~ 960 ℃) for 1min, and then burns the test sample vertically with the specified pressure (1.0N) for 30s.

Determine the fire hazard of finished electrical and electronic equipment depending on whether the test sample and bedding ignite or hold on fire; determine the ignition, ignition temperature (GWIT), flammability and flammability of solid insulating materials and other solid flammable materials Index (GWFI).

Glow wire testing

Test content

|

Test Standard |

Sample |

Sample quantity |

|

IEC60695-2-11:2014 |

Finished product |

At least 1 piece |

|

GB/T 5169-11-2006 |

||

|

IEC 60695-2-12:2010, AMD.1-2014 |

There must be a larger size plane (at least 60mm*60mm), the preferred thickness is 0.75+/-0.1mm, 1.5+, -0.1 password, 3.0+/-0.2mm (flammable) GWFI |

30 pieces |

|

GB/T 5169-12-2013 |

||

|

IEC 60695-2-13:2010, AMD。1-2014 |

There must be a larger size plane (at least 60mm*60mm), the preferred thickness is 0.75+/-0.1mm, 1.5+, -0.1 password, 3.0+/-0.2mm (flammable) GWFI |

30 Pieces |

LISUN ZRS-3H Glow-wire Test Apparatus is according to IEC60695-2-1, IEC60695-2-10, IEC60695-2-11, IEC60695-2-12, IEC60695-2-13 (GB/T5169.10, GBT5169.11, GBT5169.12, GB/T5169.13) < basic testing methods of Glow wire, basic testing methods of Glow wire device>, UL 746A, IEC829, DIN695 and VDE0471.

What is glow wire test?

The Glow wire tester ZRS-3H/ZRS-3HS is suitable for resistance to abnormal heat and fire test on lighting lamps, electronic products and household appliances. It uses high-temperature coating spraying on steel structure and imported instrument display, with easy operation and stable performance. The glow wire testing equipment is applicable to flame resistance test of all levels of QC departments and corresponding enterprises.

Description of test conditions and selection of test samples

If possible, the test sample should be a complete finished product. The selection of the test sample shall ensure that the test conditions are not significantly different from those existing in normal use, such as shape, ventilation, thermal stress effects and the effects of possible flames or burning particles or glowing particles falling near the test sample.

If the test cannot be performed on a complete finished product, or unless the relevant specifications are specified, one of the following methods can be used:

a) Cut a piece in the components that need to be tested;

b) Open a small hole on the complete finished product to contact the burning silk;

(The size of the test sample plane should be: length ≥60mm; width (inner side of the fixture) ≥60mm; thickness: 0.75 ± 0.1mm, 1.5 ± 0.1mm or 3.0 ± 0.2mm;)

Test requirements

In addition to the provisions of Chapter 8 of GB/T 5169.10-2006, unless there are other regulations, the top of the hot wire should be applied to the top part of the test sample when the test sample is installed. The burning silk should be kept as well as more as possible.

When there are more tests on the same test sample than one point, it should be noted that the deterioration caused by the previous test cannot affect the results of the test to be done later.

When there are no detailed regulations on the area where the device is suffered from thermal stress during the normal use period, the top of the burning wire should be applied to the thinnest part of the test sample, and the edge of the test sample should be not less than 15mm.

During the test, the test sample is fixed on the experimental device, but the additional mechanical stress should not be passed to the test sample.

Evaluation of test results

Unless there are other regulations on the relevant specifications, if the test sample is not burned or burned, or all meets the following circumstances, it is considered that the burning wire test is passed:

a) If the flame or burning of the test sample is extinguished within 30s after moving the burning wire, that is, TE ≤TA+30s;

b) When the bottom layer of the packaged silk paper is used, silk paper should not be burned.

Operation Steps:

1. Connect the burning box power switch. And make the sample rack leave a certain distance (press the reset key).

2. Press the reset key to reset the three timers, set the burning time according to the standard requirements, and let the button time and flame extinguish the button under the timer bounce (the button indicator is extinguished).

3. Press the heating button to access the current, and adjust the “current adjustment” knob on the heating power supply clockwise. Generally, it is generally heated at about 100 ° C with a large current. , The closer to the slower, the relationship between the hot wire temperature and the current (reference value) is roughly as follows:

Temperature_ ℃ 550 650 750 850 950

Heating current_s 60 85 100 115 130

The hot red temperature is about 650 ° C. After the current is roughly adjusted, the temperature takes a certain lag time (2 minutes) to achieve stability, and it can be fine -tuned by referring to the display value of the temperature table.

4. After the temperature is stable, press the “forward” button, and the car will move forward. When the sample is in contact with the burning silk, the car stops right at this time. The instrument automatically performs timing. After the illustration description is to be preset, the sample rack is automatically retreated. When the sample is flame in the test, press ” “TI stop button”, when the flame is out, you should press the “TE stop button”. If you want to stop the test in the middle, you can press the “reset” button. At this time, the sample rack will also automatically leave the hot wire.

5. This device has a delayed cutting of heating power. When the burning time exceeds 5 minutes, the heating power is automatically cut off. If you need to restart, press the “reset” button.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *