Introduction:

To guarantee the electromagnetic compatibility (EMC) of electronic devices and systems, EMI testing is essential. The manual testing process is increasingly inefficient and time-consuming due to the growing complexity and variety of electrical items. However, modern EMI test receivers are equipped with automated testing and data processing features, greatly simplifying the testing procedure.

This article will discuss the advantages and methods for automated testing and data analysis utilizing EMI test receivers, which will help engineers conduct EMI evaluations more quickly, accurately, and thoroughly.

Benefits of Automated Testing:

There are several benefits of using EMI test receivers to automate testing compared to traditional methods of testing:

- Time Efficiency: The human configuration and measurement setup steps that are normally required for testing are rendered unnecessary thanks to automated testing’s elimination of such steps. Continuous testing and more rapid EMI assessments may be achieved via the use of pre-programmed test routines.

- Consistency and Reproducibility: Tests are guaranteed to be repeatable and consistent when automated testing is used. The results are becoming more reliable and easier to reproduce as a result of the reduction in human error and variability brought about by the standardized testing sequences and parameters.

- Increased Test Coverage: Test iterations may be conducted more quickly and more often by developers when they use automated testing. The performance of the device may now be assessed in a more comprehensive selection of real-world scenarios thanks to this enlarged set of tests.

- Resource Optimization: By automating routine and time-consuming tasks, engineers may be able to better manage their time as well as their resources. Because their testing is automated, they are able to devote more time and energy to evaluating data, resolving difficulties, and developing preventive measures. You can get the best EMI test receivers from LISUN.

Test Sequence Automation:

Utilizing the automated test sequences that are made available by EMI test receivers may help engineers save time and reduce the amount of work they put in. The following are some of the most essential components of automated test sequences:

- Predefined Test Parameters: Engineers are able to select and store numerous test settings, such as frequency range, measurement bandwidth, and detector type, for the various EMI tests that they do. Because these variables are easily accessible, there is no longer a need for a personalized configuration before beginning each new cycle of testing.

- Sequencing and Synchronization: When generating test sequences, the order of the various tests as well as their duration may be set. The use of EMI test receivers makes the synchronization of several instruments, the taking of measurements, and the capturing of data much simpler tasks.

- Scripting and Programming: APIs (Application Programming Interfaces) and scripting languages are examples of programming interfaces offered by EMI test receivers, which facilitate the creation of bespoke test scripts by engineers. These scripts streamline and personalize the testing procedure by automating difficult test cases, data processing, and analysis of results.

Real-Time Data Acquisition and Analysis:

Engineers may get rapid insights into EMI concerns via automated testing utilizing EMI test receivers, which allows for real-time data capture and analysis. Important features of collecting and analyzing data in real time include:

- Live Spectrum Monitoring: EMI test receivers will keep a constant eye on the frequency spectrum while the tests are being performed on them. When engineers have the ability to see the spectrum in real time, it makes it much simpler for them to locate and remove the sources of interference or signals that were not anticipated.

- Event Triggering and Recording: Triggering on events like frequency peaks or amplitude thresholds allows EMI test receivers to automatically capture data for analysis. This function aids in the detection of rare or infrequent interference occurrences that may otherwise go unnoticed during routine testing.

- Statistical Analysis and Reporting: In order to measure and evaluate the extent of EMI concerns, modern EMI test receivers include statistical analytic capabilities. Statistics like peak hold, RMS (Root Mean Square), and probability density functions may be taken in real time, allowing engineers to monitor EMI signal behavior, spot patterns, and provide in-depth reports for regulatory compliance purposes.

- Post-Processing and Data Management: EMI test receivers make it easy to filter, average, and visualize collected data after the fact. Engineers are better able to make inferences from the data they collect and analyze by using these qualities to compare test results, identify important EMI characteristics, and more. Engineers may easily save, organize, and retrieve test data thanks to the data management features provided by EMI test receivers.

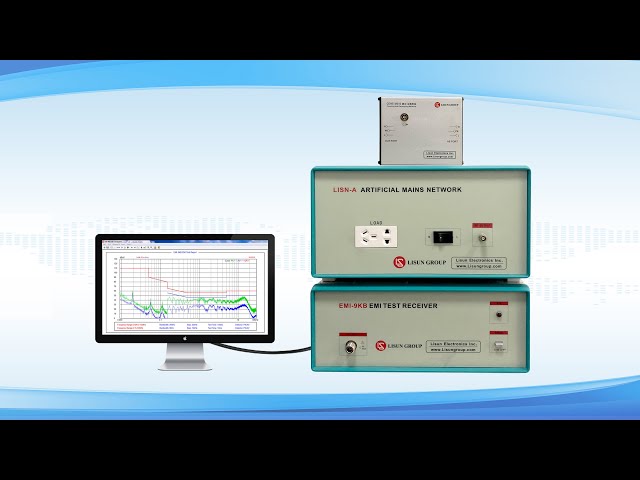

EMI-9KB EMI Test Receiver

Test Result Analysis and Interpretation:

Automated testing using EMI test receivers streamlines data processing and report generation. The Analysis and Interpretation of Test Results:

- Pass/Fail Criteria: Based on external regulations and internal standards, engineers might set pass/fail criteria. Automatic evaluation of measured data against these criteria, with instant pass/fail signals, is made possible by the use of EMI test receivers in conjunction with automated testing software.

- Data Visualization: Spectrum plots, waterfall displays, and time-domain waveforms are just some of the graphical representations of test data that may be obtained from an EMI test receiver. These representations are useful for finding EMI problems, learning about interference, and pinpointing trouble spots in the frequency domain.

- Comparative Analysis: Using automated testing, engineers may evaluate variations in device, prototype, or design iteration performance. Engineers can enhance the EMC properties of electronic goods by identifying design changes, validating mitigation measures, and comparing EMI performance across numerous circumstances.

- Diagnostic Tools and Troubleshooting: Tools like spectrogram analysis, signal correlation, and signal demodulation are available in EMI test receivers to aid in the diagnosis of EMI problems. Engineers may utilize these instruments to determine the source of interference, separate it from any potential internal or external sources, and plan for appropriate countermeasures.

Integration with Test Automation Systems:

The overall testing efficiency may be improved by integrating EMI test receivers into bigger test automation systems. The following benefits are gained by integration with test automation systems:

- Test Plan Management: Engineers are able to build, schedule, and keep tabs on EMI tests alongside other functional or performance tests with the use of test automation systems’ centralized test plan management. This unification improves overall testing efficiency and guarantees thorough test coverage.

- Data Exchange and Reporting: When EMI test receivers are integrated with test automation systems, data may be sent without any interruptions. By consolidating data, this integration allows for a more complete picture of the device’s efficacy to be reported.

- Test Workflow Automation: The whole testing process, from start to finish, may be automated with the help of a test automation system. Faster time-to-market is the result of this integration’s elimination of manual involvement, reduction of human error, and acceleration of the testing process.

- Scalability and Flexibility: Scalability and adaptability to a wide variety of test configurations and changes are hallmarks of effective test automation systems. Efficient testing of a wide range of electrical devices is made possible by the ease with which engineers may modify test sequences, parameters, and analysis modules to match individual needs.

Conclusion:

EMI testing is revolutionized by automated testing and data processing using EMI test receivers, which provides time savings, consistency of findings, expanded test coverage, and optimized use of available resources.

Engineers can streamline the EMI testing workflow, improve testing efficiency, and achieve more accurate and comprehensive EMI assessments by automating test sequences, using real-time data acquisition and analysis, integrating with test automation systems, and making use of advanced diagnostic tools.

To assure electromagnetic compatibility and improve the overall quality and dependability of electronic goods, automated testing and data analysis procedures using EMI test receivers are crucial in today’s market.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Tags:

EMI-9KB