Recently, a news broke the circle of friends: the United States released a test report on Chinese masks, and over 80% of Chinese companies were suddenly “deprived” of export authorization! Late at night on May 7th, Beijing time, the US Centers for Disease Control and Prevention (CDC) suddenly issued a test report for Chinese masks through its official website, and 105 Chinese masks were tested and announced.

In the announcement called “NPPTL Respirator Assessments to Support the COVID-19 Response”, the CDC pointed out that all samples were tested using the improved version of the NIOSH standard test procedure (STP) TEB-APR-STP-0059, and only the particles were evaluated. For the efficiency of the filter, the CDC has also published a list of tested companies and the test results of the filtering efficiency. The notice lists the company name, product type, implementation standards, test results, etc. There are some problematic products. Please click the blue link. Before that, there were nearly 100 Chinese mask companies on the “authorized mask” list, and suddenly there were only 14! In other words, more than 80% of Chinese mask companies have lost the whitelist qualification for export to the US market!

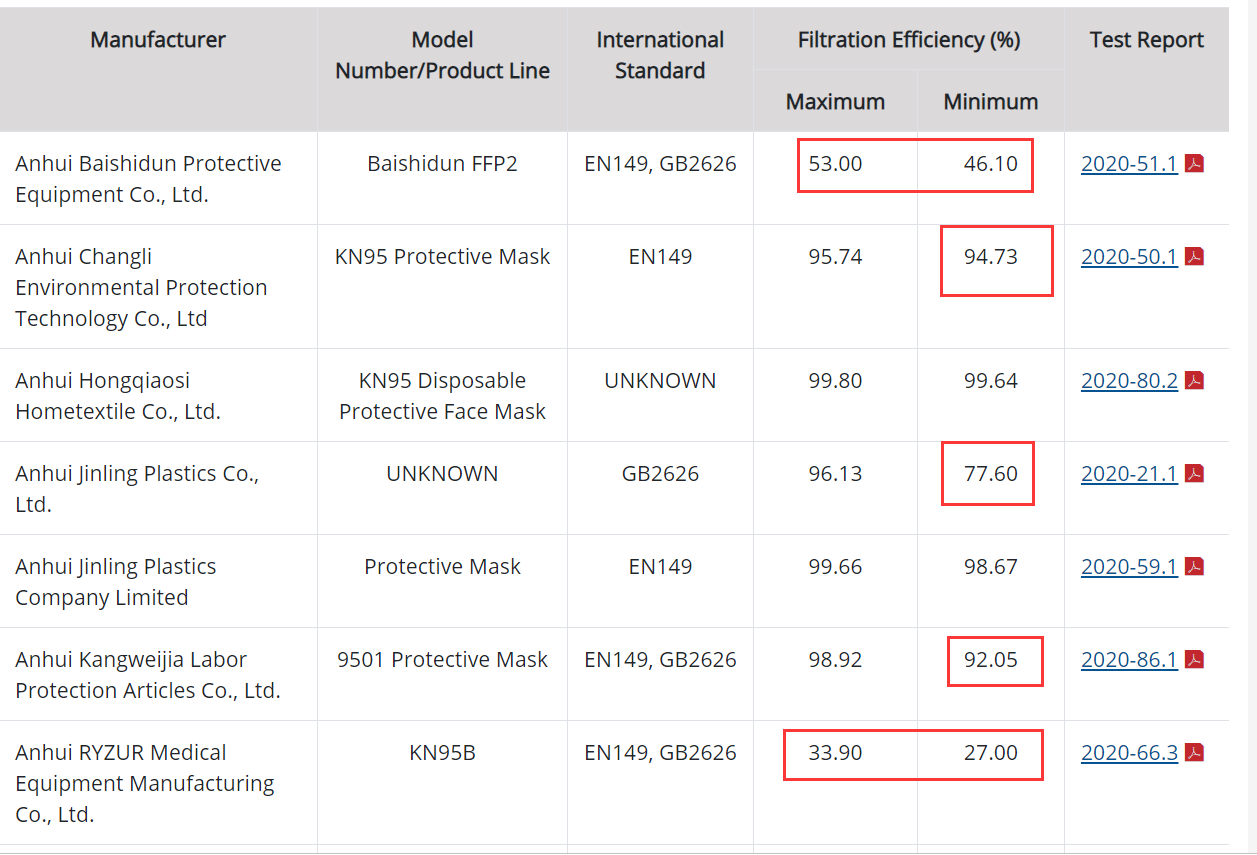

After review the above documents and the PDF report, and find that 80% of the companies’ particulate filterability (usually refers to PFE is 0.3um) is not qualified by CDC/FDA random inspection, that is, PFE<95% (the red part of the screenshot below is not up to standard), some companies have Only 40-50%. The author also has to worry about this part of the enterprise, what should the cargo owners who have purchased the original white list enterprises do? What should be done with the original whitelist masks that are already flying in the air and floating on the sea?

The data from CDC official website screenshot

Worrying to worry, you have to return to reality. The boss who in the mask industry must think and face a quality problem: before the new crown special drugs or vaccines come out, the demand for masks will still be strong. But as the international epidemic continues Better, the mask industry will inevitably become rational. Those enterprises that can not really produce high quality and fully meet the standards will be eliminated by the market. For the mask core material melt-blown cloth companies, the days when the PFE filterability is temporarily improved by special means, and the cloth can be collected from the production line may be gone forever, and the mask companies may require the melt-blown cloth to provide The PFE filterability test result of keeping for 3-7 days, then the problem is coming, can your meltblown cloth still reach 95% after keeping for 3-7 days?

The author visited a number of melt-blown cloth production manufacture and equipment installation companies, and found that the melt-blown cloth’s PFE filter is chaotic. If you want to achieve the PFE filterability of meltblown cloth, you must choose brand production equipment and processes, raw materials from regular manufacturers and electrified masterbatch, using professional corona electrostatic electret treatment. The manufacture with a PFE filterability of less than 50% before adding static electricity, simply by increasing the voltage and current of the electrostatic electret. It can temporarily significantly increased the PFE filterability to more than 95%, but the static electricity dropped after 5-7 days If the optical filter property is returned to its original shape. It will be rejected by the mask factory. Therefore, after 5-7 days, your meltblown PFE filter performance is stable to 95% is really 95%!

LISUN is manufacturing the latest high-frequency version of electrostatic electret generator. Compared with other electrostatic electret generator on the market, LISUN has the following characteristics:

The next notice: PFE filterability test results after 3-5 days after adding static electricity to the meltblown cloth in several static electret devices on the market!

Tags:ESD-RPBYour email address will not be published. Required fields are marked *