The measurement of color is generally divided into light source color and object color, which is why the standard light source must be used as the most illuminating system in the research and development of colorimeter. In the past, we learned from colorimetry that the color of light source can directly affect the visual stimulation result of color, which is the change of color signal transmitted by visual nerve to the brain. Therefore, the use of unified standard lighting source is the basis for correct and reliable color detection.

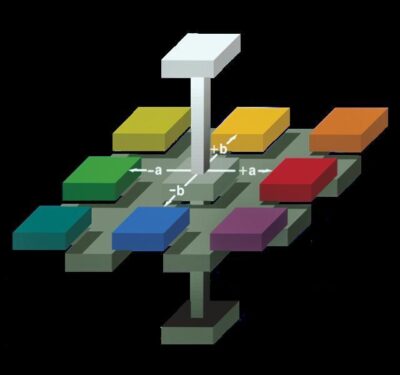

CD-320PRO Detail Pictures

Object measurement can also be divided into fluorescent substance measurement and non fluorescent substance measurement. In practice, there are many non fluorescent substances measured by colorimeter. The existing color measurement methods include visual method, photoelectric integration method and spectrophotometry. These three methods have been applied in industry, but the application scope and industry are different according to different color requirements.

With the improvement of science and technology and the rise of people’s requirements for color quality, the results of visual color measurement can not meet the requirements of industrial production in many cases. Therefore, photoelectric integration method and spectrophotometer are widely used in industry to adhere to color. Photoelectric integration method uses photoelectric integration colorimeter, computer software and operator’s experience to measure together. However, this method requires less precision, and is applicable to color measurement and analysis of objects that only need to control the color of objects and do not require high measurement accuracy. The spectrophotometer is used to measure some industries and products with relatively high precision requirements and fine data analysis based on the experience of operators by using spectrophotometer and computer color matching software.

Colorimetric principles are now widely used in all walks of life, and continue to develop into some special industries, such as archaeology, quarantine, and so on.

Reasons for unadjustable color difference:

If the color difference problem that cannot be adjusted occurs in industrial production, it is mainly because the cause of color difference has not been found. Because there are many color problems in the design of a product, we need to use a colorimeter to strictly control every possible part of the production process to be recorded. This process should not be afraid of trouble.

In industrial production, the color difference may be caused by one reason or by the joint action of multiple reasons. If we only adjust one factor in the adjustment, it is difficult to really solve the problem. This requires us to strictly control and adjust every link in the production process, and the colorimeter must not be lacking in the mass production industry. Those who have a little knowledge of the colorimeter know that this instrument is mainly used to measure the Lab value, but we cannot only look at these three data when analyzing the color difference problem, and there are many factors to take into account.

L a b 3D coordinate representation

For example, the color difference value of paint film is required in the paint industry. We only see that the Lab value in the color difference meter is completely inaccurate. We also need to analyze the color difference according to the existing information and the matching of primer and finish film thickness, painting method, paint selection and other aspects of the instrument. The color difference meter only provides a reliable analysis direction for us to analyze the cause of color difference, and does not directly tell us where the color difference comes from.

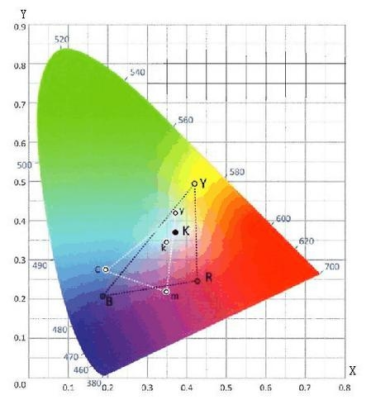

CIELAB color space

The color difference of the same color in different batches may be different under the same process control, which is related to the proportion and construction of the paint itself. Therefore, the adjustment of color difference cannot always follow the usual way of thinking. It is necessary to correctly find the reasons and suit the remedy to the case. There are differences in the coating process proportion (solid content, etc.), process operation, production technology, etc. of different manufacturers, so different methods should be used to adjust the color difference of different manufacturers.

It is always a meticulous job to detect and control the color difference value of products. Our staff must form a good habit in the production process, measure and record in real time.

LISUN lauched Portable Colorimeter/Chroma Meter is an innovation color measuring tool with powerful configuration to make color measurement easier and more professional; It support Bluetooth to connect with Android and ISO devices, Portable Colorimeter/Chroma Meter will take you into a new world of color management; It can be widely used to measure color value, color difference value and find similar color from color cards for printing industry, paint industry, textile industry, etc.

Tags:CD-320PROYour email address will not be published. Required fields are marked *