Color difference controlled by spectrophotometer:

The more advanced spectroscopic type of colorimeter, also known as the spectrophotometer, contains an optical element that can separate light and dispersion. The spectrophotometer generally uses prism, grating, interference filter, adjustable or discontinuous series of monochromatic light sources to achieve light splitting, and then analyzes the single color information according to the dispersion principle to achieve color number. The spectrophotometer can finally display the chromaticity information according to the internal chromaticity space and calculation formula, and output it in digital form. In addition, the spectrophotometer can also analyze the potential spectral data information according to the chromaticity data.

Double optical path spectral analysis technology

The spectrophotometer is designed for visual colorimetric data comparison and simulation, as well as an important auxiliary tool for computer color matching, which can help major manufacturers perfectly complete the analysis, processing and monitoring of spectral and colorimetric information. A key data equation – color tolerance equation will be involved in the use of the spectrophotometer. In fact, it is what we usually call tolerance range. In industrial batch production, there is tolerance to control products and conformity, which is fast and reasonable.

D/8 Geometry

In order to measure the product and control the color difference, the spectrophotometer is the same as the ordinary colorimeter. First, measure the information of the standard sample product, and then compare the color information of the measured sample to get the color difference data.

In fact, color measurement and management are generally the same, except that the spectrophotometer has higher accuracy and more comprehensive functions.

Factors Affecting Color Difference of Car Body Paint:

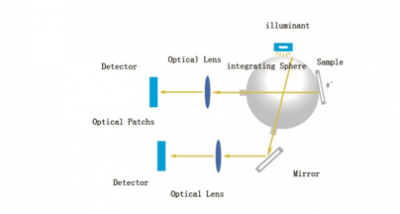

spectrophotometer is a precision instrument for color detection commonly used in industry at present. It can form a professional color matching management system together with computer color matching management software. To provide reliable color quality assurance for modern industrial production, the colorimeter simulates the characteristics of human eye observation. The standard light source is used as the internal lighting system, the high power integrating sphere is used as the optical path conversion device, and the intelligent light splitting system determines the spectral system. Finally, the original optical signal is converted into a digital display to the operator through high-precision micro processing. The internal light conversion of the colorimeter is different for different instruments.

The color of the car body directly affects its overall appearance, so the car manufacturer’s requirements on the color of its car body can be said to be very strict. Any small defect may cause customer dissatisfaction, directly lead to quality degradation, and the company’s brand is injured. In order to avoid the loss caused by this phenomenon in the automobile production process, the multi angle colorimeter is generally used to control the color information of products.

The paints and varnishes used for automobiles are generally divided into two categories: monochrome paint and flash paint. Monochromatic paint reflects the incident light by pigment particles. Generally, it will not produce color variation with angle. It is easier to measure with color difference instrument. Relatively speaking, flash paint has a layer of mirror coating on its surface, which can produce diffusion, causing the incident light to refract out at different emission angles. It is more complicated and troublesome to measure.

SCI/SCE measurement

The flash paint is generally composed of transparent plastic grease solution, colored pigment and flash aluminum powder or pearlescent powder. In this way, the paint is applied to the car shell to make the car look high-end and elegant. However, the flash aluminum powder, pearlescent powder and plastic grease coating in this paint will produce diffuse reflection after drying together. The incident light will diffuse reflection at both ends, plane mirror reflection and transmission.

For metallic flash paint, aluminum powder is arranged in different layers in the paint film, and the reflected light is also different. Among them, 15 º 25 ° is the near specular reflection angle, and its specular reflection color is mainly affected by the directional arrangement of metal sheets or pearlescent pigments. 45 º is a straight angle of view, which is the best angle for visual template. It is affected by the arrangement of aluminum powder and coloring pigment. 75 º and 110 º are side view angles, which are most affected by colored pigments.

LISUN lauched Benchtop Spectrophotometer (Reflectance and Transmittance) DSCD-920 adopts 7 inches touch screen, full wavelength range, Android operate system. Illumination : reflectance D/8° and transmittance D/0°(UV included / UV excluded), high accuracy for color measurement, large storage memory, PC software, because of above advantages, it is used in laboratory for color analysis and communication.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *