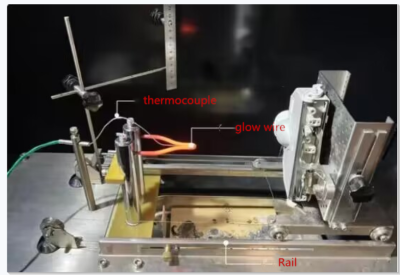

The Glow-wire Tester is used to test the stability of electronic and electrical products during operation, and the flame retardant performance of electronic products in the electrical and electronic industry. The Glow-wire test itself is a fixed specification material Ni/Cr (80/20) alloy wire heating wire. During the test, the thermocouple conducts heat to the specified temperature, and the top of the Glow-wire contacts the sample to the standard required time, and then observe and measure its state. The test range depends on a specific test procedure.

LISUN Glow wire test ZRS-3H/ZRS-3HS is suitable for resistance to abnormal heat and fire test on lighting lamps, electronic products and household appliances. It uses high-temperature coating spraying on steel structure and imported instrument display, with easy operation and stable performance. The glow wire testing equipment is applicable to flame resistance test of all levels of QC departments and corresponding enterprises.

In the Glow-wire Test, the Glow-wire U-shaped heating wire is used as the heat conduction source. This test method is used to check the fire safety performance of products during use or failure. Heated or illuminated parts can be considered as short-term ignition sources. Due to loose connections and poor contact, electrical products and their components and parts will be overheated, and it is also necessary to pay attention to the risks of textile seating cover, table cloth or curtain fire, such as exposure to cigarette burns.

Glow Wire Teste Process

Glow Wire Tester Hot Wire Tester Temperature Calibration Methods:

1. The silver foil conforming standards include: IEC60695-2-10, GB/T5169.10-2006, GB/T5169.13-2006 and GB4706.1, etc. Silver foil is also used to calibrate the temperature of Hot Wire Testers for scientific research units, schools, factories, laboratory and testing agencies.

2. It is not possible to measure an accurate value of the Glow Wire temperature up to 960°C with other more intuitive instruments as the melting point of silver is 960°C, so high purity (99.9%) silver foil is used for the calibration.

3. Cut a piece of silver foil with a purity of not less than 99.8%, a thickness of about 0.06mm and an area of about 2mm².

4. Hold it by tweezers and place it on top of the Hot Wire U-shaped heating wire head, slowly applying the Glow-wire apparatus. When the temperature is 960°C the silver foil melts (condenses into mercury granules on the surface of the U-shaped wire head), indicating that the Hot Wire temperature has reached the required standard. Clean the Hot Wire head of silver residue after each calibration, such as soft steel wire brush or soft metal scraper.

5. If the calibration is not qualified, replace the old Glow wire with a new one and recalibrate the temperature.

6. The new standard of IEC60695-2-10:2013 requires 960°C± 15°C, which is a strict requirement for Glow-wire Test Apparatus, Glow-wire Tester, Glow-wire Test Meter and Glow-wire Testing Device instrument manufacturers.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *