The Salt spray test Chamber is used to conduct salt spray corrosive tests on components, parts, electronic and electrical components, metal materials, and industrial products. The salt fog test chamber complies with the following specifications: IEC60068-2-11 (GB/T2423.17), GB/T10125, GB/T1771, ISO9227, ASTM-B117, GB/T2423-18, QBT3826, QBT3827, IEC 60068-2-52, ASTM-B368, MIL-STD-202, EIA-364-26, GJB150, DIN50021-75, ISO3768.

Salt Spray Test Chamber YWX/Q-010

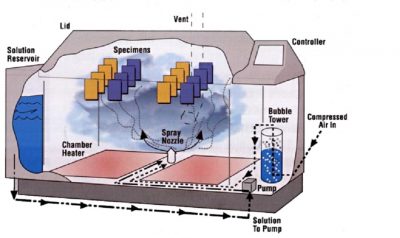

Typically, this test is performed in accordance with the ASTM B117 or ISO 9227 testing procedures. The samples being compared are placed in an enclosed chamber and then exposed to a thick metal fog that simulates severely corrosive conditions. The test employs a sodium chloride solution with a pH range of 6.5 to 7.2.

This test typically lasts 8 to 3,000 hours. Though, as previously stated, there are a variety of other corrosion tests, the salt spray test is very common. However, experts are divided on how closely it reflects real-life conditions. Some experts, for example, question the test’s suitability because it does not involve exposure to salt chemicals.

There are a number of compelling reasons to conduct a salt spray test, the most important of which is to determine how corrosion will affect your specimen. Different surfaces and metals can have different levels of corrosion resistance, and this test allows you to compare them. Furthermore, the test allows you to determine a surface’s proclivity to corrode in the event that it is scratched, as well as assess the stickiness of the coating.

The following are a few examples of relative salt spray test results:

• Black Oxide – Samples show corrosion after 24 to 96 hours

• Ruspert Coating (200 & 300) – Samples show no traces of red rust after 1000 hours

• Powder Coating – Samples can last up to 500 hours before rusting

• Stainless steel (304 & 316) – Results vary depending on the finish However, after 1000 hours, the majority of samples in this category show almost no corrosion.

Salt spray testing is a laboratory simulation of a corrosive saline environment. It is used as an accelerated means of testing the ability of surface coatings to withstand atmospheric corrosion. Also known as salt fog testing, it is one of the oldest testing methods used in the HVAC-R coatings industry, and for this reason, is often referred to when selecting HVAC-R coatings.

Heresite Protective Coatings uses salt spray testing in two ways as we develop and evaluate our HVAC-R and radiator coatings. Salt spray testing is used as a stand-alone corrosion resistance test and also as a component of ISO 12944-9 (previously known as ISO 20340). For both tests, the salt spray process is handled the same way, conducted per ASTM B-117.

• First, small panels (typically 3×5 inches or 4×6 inches) are prepared with the coating to be tested. The edges and the backs of the panels are protected, typically with tape. Then the front of the panel is “scribed” with a sharp tool to produce a scratch through the coating to the metal substrate.

• After the panel is prepared, it is placed inside the test cabinet. The cabinet contains racks to hold the panels in position as specified by ASTM B-117 – tilted back 15 to 30 degrees from the vertical.

• The cabinet is then closed, and a 5% salt solution is delivered at a constant rate and temperature into the cabinet through an atomizer. Salt fog is sprayed upwards so that droplets will descend and settle on the panels.

• After this point, there will be periodic checks of the test panels, as well as monitoring of the salt spray cabinet to ensure that it functions properly throughout the duration of the test. During these brief evaluations of the panels, it is determined whether the test is progressing as expected or if the coating on the test panels is failing prematurely.

Although each laboratory has a slightly different set up, the basics of the test are as described above. Heresite is fortunate to have a cabinet with a digital readout displaying the total hours of test cabinet operation, as well as alarms that will notify us about a variety of important things, such as if the salt solution level becomes low. These features are important because some salt spray tests run for extremely long times. For example, Heresite P-413 was tested against ASTM B-117 for 6,000+ hours. That’s 250 straight days (or a little over 8 months) of continuous salt spray.

salt spray test

Heresite also uses salt spray testing when conducting test using the ISO 12944-9 standard. Heresite’s P-413, ES-606, and HereShield have all been tested against this standard. Although both ASTM B-117 and ISO 12944-9 are used to measure corrosion protection, there are some significant differences between the two tests. Unlike B-117, which is a static salt spray only test, ISO 12944-9 is a cyclic test, where the panels are tested for 72 hours of UV exposure, followed by 72 hours of salt spray, then 24 hours of freezing (for a total of 168 hours / one week. That cycle (UV / salt spray / freezing) is repeated for 25 weeks, for a total of 4,200 hours.

Although neither test is an actual outdoor environment, ISO 12944-9 is much more like the extreme weather cycles that HVAC-R units are often exposed to in the real world. For this reason, SSPC (The Society for Protective Coatings) has concluded that “combined corrosion / weathering is a substantial improvement to the traditional salt spray test (ASTM B117) in terms of reproducing atmospheric corrosion in an accelerated fashion.”

It should be noted that, contrary to popular belief, the Salt spray test, like other corrosion tests, does not show any correlation. The test for X hours does not imply that the coating will resist corrosion for a certain number of years. This is because rust takes years to form in real-life situations. As a result, the best course of action is to use this test solely as a predictor of real-world outcomes.

To fully comprehend the preceding, the Salt spray test should be viewed as a quality-control measure used to ensure that process control is on track and accurate. In other words, the results of this testing are not indicative of real-world outcomes. To give you an example, if you know that zinc plating lasts 96 hours and powder coating lasts 500 hours but your test sample doesn’t, it means that something went wrong with our process.

On the same note, you should proceed with caution if you draw the conclusion from these figures that powder coating is more resistant than zinc plating. Such an inference would be misleading because, as previously stated, spray salt rating is not a predictor of which coating will outperform the other in the real world.

Consider hot dip galvanizing, which can last between 75 and 100 years with no maintenance. However, it fails miserably in this test. This is because its actual endurance in the real world is dependent on other factors such as the gradual formation of a glassy skin of corrosion products, which does not form in this type of test.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *