Requirements for rotary appliances of IEC60335 Standard

General

Scarifiers with rear discharge openings shall have a movable deflector, the closing torque of which shall not be less than0,30 Nm for machines with a cutting width of 300 mm or less, and not less than 0,40 Nm for machines with a cutting width of 300 mm to 600 mm.

Discharge openings (chutes)

When open discharge chutes are provided, no tangential line from the cutting means tip circle in or above the plane of the cutting means tip circle and in the direction of rotation of the cutting means shall intersect the operator target area without first contacting the cutting means enclosure or guard.

Access to cutting means

Inadvertent access to the cutting means by the feet during operation shall be prevented so far as is reasonably practicable.

On the operator side, the distance between the blade tip circle and the rear housing or a deflector shall be at least 120 mm (see Figure 101).

IEC 60335-2-92 Figure 101

Scarifiers with discharge openings shall have deflectors (e.g. catchers, baffle plates) which catch thrown objects and prevent inadvertent access by the operator’s feet.

Movable deflectors shall return to the closed position automatically. Instructions shall be affixed to the scarifier near the discharge opening and to the catcher adapter, if one is used, stating that the scarifier shall not be operated without either the entire catcher or the guard in place.

Compliance is checked by inspection.

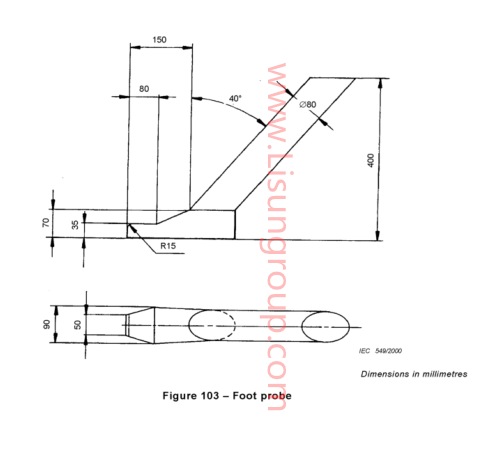

For the guards at the sides of the machine, compliance is checked by the following test using the foot probe (Figure 103) as illustrated in Figure 104.

IEC 60335 Standard Test Foot Probe

The scarifier is placed on a hard flat surface, the guards or deflectors or both being in the normal operating position on the cutting means housing and the support members (wheels) in contact with the supporting surface. The test is conducted under static conditions.

Single axle scarifiers are to be positioned as instructed by the manufacturer or so that the handle grip is 900 mm above the supporting surface.

The tests are made with the cutting means in the highest and lowest cutting position. The base of the test probe is held horizontally at any height and then inclined up to 15°forward or backward from the horizontal. The probe is applied at any point of the housing side.

The test probe shall not enter the path of the cutting means assembly. The test probe shall not lift the scarifier or any of its parts from the supporting surface.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *