The ZRS-3H Glow-wire Test Apparatus is according to IEC60695-2-1, IEC60695-2-10, IEC60695-2-11, IEC60695-2-12, IEC60695-2-13 (GB/T5169.10, GBT5169.11, GBT5169.12, GB/T5169.13) < basic testing methods of Glow wire, basic testing methods of Glow wire device>, UL 746A, IEC829, DIN695 and VDE0471.

What is glow wire test?

The Glow wire tester ZRS-3H/ZRS-3HS is suitable for resistance to abnormal heat and fire test on lighting lamps, electronic products and household appliances. It uses high-temperature coating spraying on steel structure and imported instrument display, with easy operation and stable performance. The glow wire testing equipment is applicable to flame resistance test of all levels of QC departments and corresponding enterprises.

Q1: Limiter position is not correct.

A1: The limiter need to be adjusted according to the sample. Different sample is with different size, so the position of the limitor need to be adjusted according to the sample. Please refer to the user manual about how to adjust.

limiter

Q2: A B C buttons on the touch screen and remote are not available.

A2: Need to click “Reset(D)” before every new test, then other buttons become clickable.

ZRS-3H glow wire test program Reset button

Q3: The temperature of the glow wire is not stable.

A3: The high temperature of the glow wire is obtained by a large current. Temperature need some time to be stable. So adjust the current slowly. Current changing too fast lead to hot wire temperature instability and bad for the equipment. Please close the door of the chamber before the test. Too much air flow will also affect the temperature of the glow wire, and fail to meet test standards. Please also use constant voltage power supply for the machine, otherwise the temperature will also fluctuate.

Q4: The glow wire won’t reach the expected temperature after long time using.

A4: Need to clean the glow wire after each test. It will affect the temperature if there is residue on the glow wire.

Q5: The temperature displayed on the screen does not match the actual temperature.

A5: The actual temperature of the glow wire can be confirmed by the silver piece. If the temperature displayed on the screen is different from the actual temperature after very long time using, you need to replace the glow wire and the thermocouple with a new set. Glow wires and thermocouples are consumables that need to be replaced after about 60 hours of cumulative operation.

Q6: After clicking the “Reset” button, click the “Left Run” button, but the carriage will still not move.

A6: Please check the proximity switch and limit switches. If metal touches the proximity switch or any limit switch is touched, the carriage cannot be controlled to move.

The proximity switch is used to control the final position of the carriage during the test:

Proximity switch of the glow wire tester

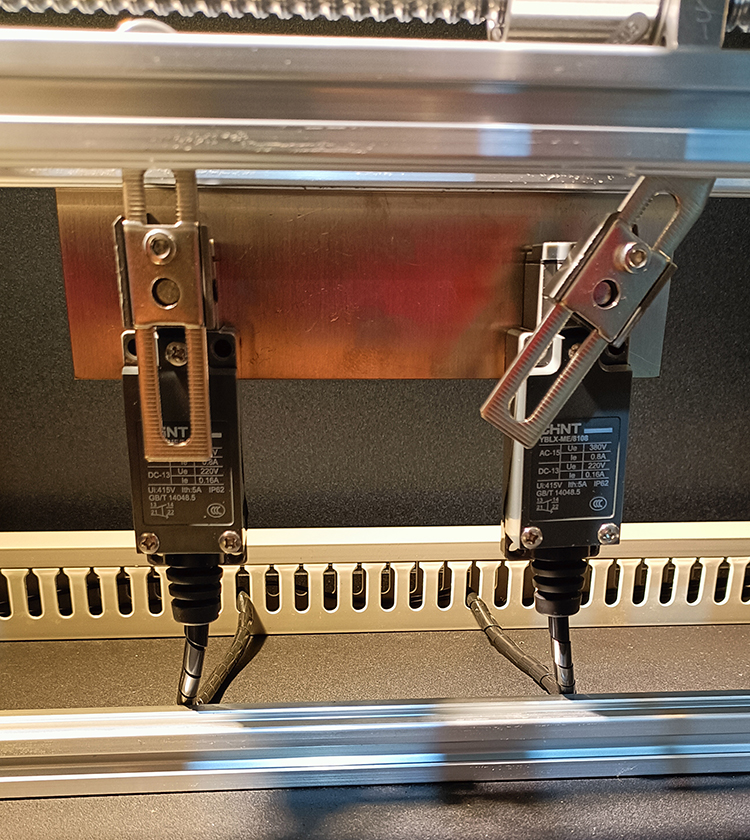

Two limit switches are used to control the maximum left and right travel of the carriage. They are located on the other side of the carriage and generally do not require any adjustment:

Limit switches of the glow wire tester

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *