12 Tests for protection against access to hazardous parts indicated by the first characteristic numeral

12.1 Access probes

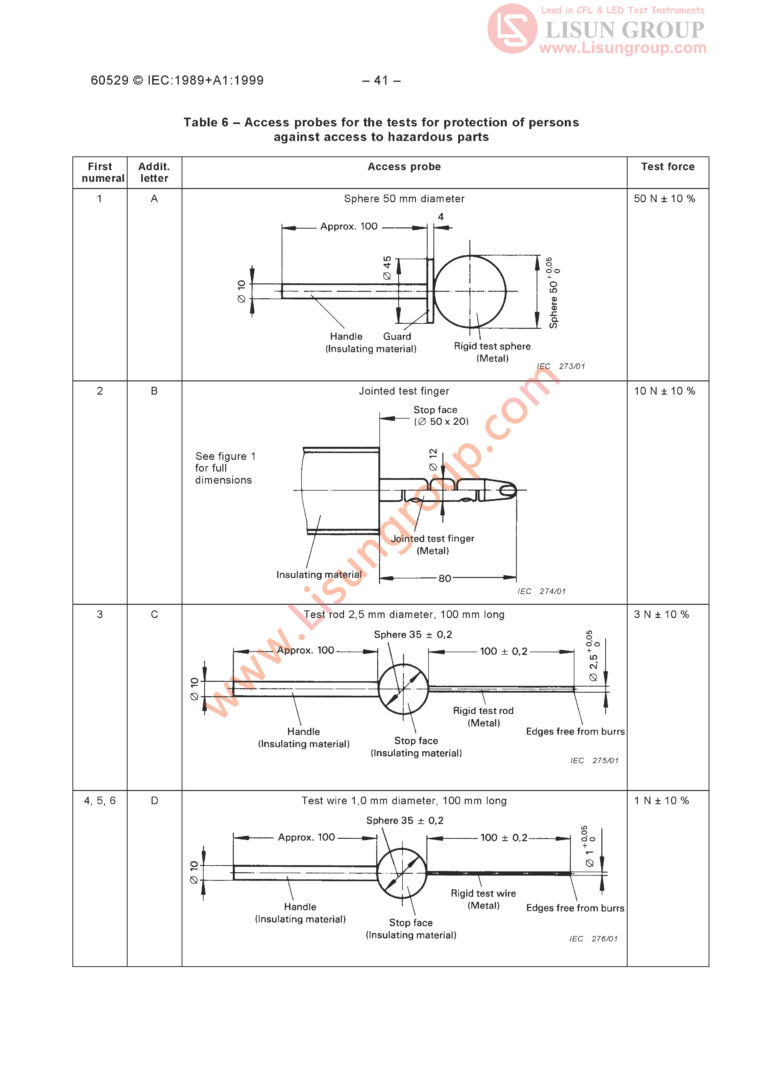

Access probes to test the protection of persons against access to hazardous parts are given in table 6.

12.2 Test conditions

The access probe is pushed against or (in case of the test for first characteristic numeral 2) inserted through any openings of the enclosure with the force specified in table 6.

For tests on low-voltage equipment, a low-voltage supply (of not less than 40 V and not more than 50 V) in series with a suitable lamp should be connected between the probe and the hazardous parts inside the enclosure. Hazardous live parts covered only with varnish or paint, or protected by oxidation or by a similar process, are covered by a metal foil electrically connected to those parts which are normally live in operation.

The signal-circuit method should also be applied to the hazardous moving parts of high-voltage equipment. Internal moving parts may be operated slowly, where this is possible.

Test Probe Kits of IEC 60529

12.3 Acceptance conditions

The protection is satisfactory if adequate clearance is kept between the access probe and hazardous parts.

For the test of first characteristic numeral 1, the access probe 50 mm diameter shall not completely pass through the opening.

For the test of first characteristic numeral 2, the jointed test finger may penetrate to its 80 mm length, but the stop face (∅ 50 mm x 20 mm) shall not pass through the opening. Starting from the straight position, both joints of the test finger shall be successively bent through an angle of up to 90° with respect to the axis of the adjoining section of the finger and shall be

placed in every possible position.

See annex A for further clarification.

Adequate clearance means:

12.3.1 For low-voltage equipment (rated voltages not exceeding 1000 Va.c. and 1 500 V d.c.)

The access probe shall not touch hazardous live parts.

If adequate clearance is verified by a signal circuit between the probe and hazardous parts, the lamp shall not light.

NOTE The attention of relevant technical committees is drawn to the fact that in some types of electrical equipment the maximum voltage produced internally (r.m.s. value or d.c. value of the working voltage) is higher than the rated voltage of the equipment. This maximum voltage should be considered when the dielectric test voltage and the adequate clearance are determined.

12.3.2 For high-voltage equipment (rated voltages exceeding 1 000 V a.c. and 1 500 V d.c.)

When the access probe is placed in the most unfavourable position(s), the equipment shall be capable of withstanding the dielectric tests as specified in the relevant product standard applicable to the equipment.

Verification may be made either by dielectric test or by inspection of the specified clearance dimension in air which would ensure that the tests would be satisfactory under the most unfavourable electric field configuration (see IEC 60071-2).

In the case where an enclosure includes sections at different voltage levels the appropriate acceptance conditions for adequate clearance shall be applied for each section.

NOTE The attention of relevant technical committees is drawn to the fact that in some types of electrical equipment the maximum voltage produced internally (r.m.s. value or d.c. value of the working voltage) is higher than the rated voltage of the equipment. This maximum voltage should be considered when the dielectric test voltage and the adequate clearance are determined.

12.3.3 For equipment with hazardous mechanical parts:

The access probe shall not touch hazardous mechanical parts.

If adequate clearance is verified by a signal circuit between the probe and hazardous parts, the lamp shall not light.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *