Hazards in industry: The generation of static electricity is inevitable in industrial production, and the hazards caused by it can be attributed to the following two mechanisms:

1. Hazards caused by electrostatic discharge (ESD): cause malfunction or malfunction of electronic equipment and cause electromagnetic interference.

2. Breakdown of integrated circuits and precision electronic components, or promote component aging, reducing production yield.

3. High-voltage electrostatic discharge can cause electric shock and endanger personal safety.

4. It is very easy to cause explosion and fire in the production place with many flammable and explosive materials or dust and oil mist.

5. Hazards caused by electrostatic attraction (ESA): Electronics industry: attracts dust, causes pollution of integrated circuits and semiconductor components, and greatly reduces the yield.

6. The damage of static electricity to the LED lamp bead, due to the heat generated by the instantaneous electric field or current, the LED lamp bead is partially injured, and the leakage current increases rapidly damage.

7. The insulating layer of the LED lamp bead is damaged by the electric field or current, resulting in the damage of the LED lamp bead and the failure to work, which is mainly manifested as a dead lamp.

Electrostatic test method:

In general, electrostatic testing is divided into two ways, one is contact electrostatic testing, and the other is non-contact electrostatic testing. Usually, the contact anti-static voltage value of electronic components is lower than the non-contact anti-static voltage value. Industrial anti-static standard: contact anti-static voltage 6kV, non-contact anti-static voltage 8kV. LISUN design ESD simulator gun (Electrostatic Discharge Generator/Electrostatic Gun/ESD Guns) is in full compliance with IEC 61000-4-2, EN61000-4-2, ISO10605, GB/T17626.2, GB/T17215.301 and GB/T17215.322.

ESD61000-2 Electrostatic Discharge Simulator

Preparation before electrostatic test:

• Connect the equipment to be tested and ensure that the equipment is functioning properly before testing.

• Connect the ESD tester, and ensure that the ground wire of the tester and the ground wire of the device are connected to each other to form a discharge loop.

Contact Static Test:

Test items include equipment chassis shell, power interface, control interface, and communication interface.

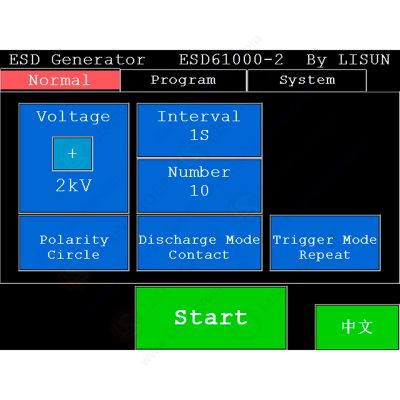

The test voltage standard, the test electrostatic voltage increases from 2kV, and increases by 2kV each time until 20kV. The test electrostatic voltage is 2kV, 4kV, 6kV, 8kV, 10kV, 12kV, 14kV, 16kV, 18kV, 20kV. Test frequency standard, test discharge is divided into two frequencies, but the number of discharges is 10 times. One frequency is 1 discharge per second and 10 consecutive discharges, which is a low-frequency electrostatic discharge test; the other frequency is 1 discharge in 0.1 second, and 10 consecutive discharges, which is a high-frequency electrostatic discharge test. The test passes the standard, the hardware is not damaged, the communication is normal, and the data is free of errors and loss.

Test stop standard. When testing a certain item, if the hardware is damaged, the communication is abnormal or any other abnormal situation, the test will not be carried out to a higher standard, but only the current test results will be counted. The test moves to the next item. In order to improve the test accuracy, you can also lower the electrostatic voltage by 1kV for the test when the test equipment is abnormal. If the test passes, increase the electrostatic voltage by 0.5kV for the test. If the test fails, continue to reduce the electrostatic voltage by 0.5kV to test and so on. The adjustment range is continuously reduced to 0.25kV, 0.125kV, etc., until the accuracy meets the requirements, and the critical electrostatic voltage test results are counted.

The test sequence is standard, the test sequence is to determine the voltage first, and then determine the frequency. The voltage from low to high and the frequency from slow to fast. That is, 2kV low frequency test, 2kV high frequency test, 4kV low frequency test, 4kV high frequency test, until 20kV low frequency test, 20kV high frequency test. In the process of improving the accuracy test, the principle of first determining the voltage and then determining the frequency is also followed to test the data standard. When testing a certain item, under a certain voltage and frequency, if the test passes 20 times in a row, it is determined to be in the current stat , the system works normally. Otherwise, count the number of errors during 20 consecutive tests, calculate the probability of errors, and fill in the test data report. Test method standard, first align the electrostatic gun with the tested item (such as: chassis, each interface), move the electrostatic gun to the surface of the tested item, require the electrostatic gun to keep vertical and in contact with the surface of the tested item, and pull the electrostatic gun trigger, after all 10 discharges are over, release the trigger of the electrostatic gun, remove the electrostatic gun from the surface of the tested item, and prepare for the next test.

ESD61000-2 ESD test LCD display

Non-contact electrostatic testing:

Test items include equipment chassis shell, power interface, control interface, and communication interface.

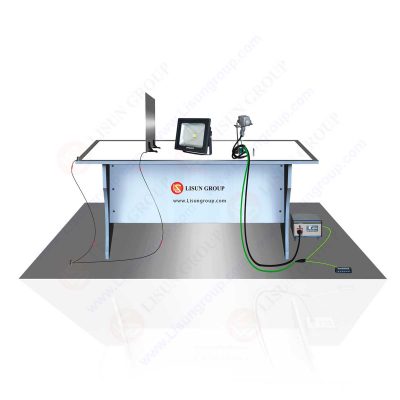

Test voltage standard, the test electrostatic voltage starts to increase from 2kV, and increases by 2kV each time until 20kV, that is, the test electrostatic voltage is 2kV, 4kV, 6kV, 8kV, 10kV, 12kV, 14kV, 16kV, 18kV, 20kV. Test passed Standard, no hardware damage, normal communication, no data error, loss, etc. It is best to use it together with the electrostatic table produced by LISUN.

ESD Standard DESK

Test stop standard. When testing a certain item, if the hardware is damaged, the communication is abnormal or any other abnormal situation, the test will not be carried out to a higher standard, but only the current test results will be counted. The test moves to the next item. In order to improve the test accuracy, you can also lower the electrostatic voltage by 1kV for the test when the test equipment is abnormal. If the test passes, increase the electrostatic voltage by 0.5kV for the test. If the test fails, continue to reduce the electrostatic voltage by 0.5kV to test and so on, the adjustment range is continuously reduced to 0.25kV, 0.125kV, etc. until the accuracy meets the requirements.

Standard test sequence, the test sequence is voltage from low to high. That is, 2kV test, 4kV test, 6kV test, until 20kV test.

Test data standard, when testing a certain item, under a certain voltage, if the test passes 20 times in a row, it is determined that the system is working normally in the current state. Otherwise, the number of errors during the 20 consecutive tests is counted. Calculate the probability of error and fill in the test data report.

The standard test method is to first align the electrostatic gun with the item to be tested (such as: chassis, each interface) with a distance of more than 5 cm, pull the trigger of the electrostatic gun, and move the electrostatic gun close to the surface of the tested item. The surface of the tested item is kept vertical. After the air discharge is over, remove the electrostatic gun from the surface of the tested item, release the trigger of the electrostatic gun, and prepare for the next test.

Note: During the test process, the test results of a certain component will vary due to individual differences in components, such as insurance, diodes, etc., which requires multiple measurements of different components to obtain the test results of all components. The average value is used as the final test result.

During the test, under normal circumstances, it is not possible to directly conduct electrostatic discharge on the chip. If there are special needs, when conducting electrostatic discharge test on a certain chip, the amplitude of each electrostatic increase should be reduced as much as possible, so that the close value of the actual value of the anti-static voltage can be better tested, making the test more accurate.

During the test, in order to ensure the accuracy of the test results, the time interval between the end of each electrostatic discharge and the start of the next electrostatic discharge should not be too small, and sufficient recovery time should be left for the system. That is, enough time for the system to release the charge , the time interval is generally 10 seconds. The next test can only be performed after the system charge is fully released.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

Your email address will not be published. Required fields are marked *