LEDs and LED luminaires with high light efficiency, longer lifetime, better energy saving and environmental friendly advantages to achieve top position on the lighting industry, like indoor and outdoor lighting application. With the introduction of various national support policies, there appeared many LED lighting products manufacturer, but the quality of LED lighting products is not good well which influence the LED lighting product’s marketing promoting more or less. According to market quality checking, the failure rate of LED lighting product reach to 39%, most of failure products related with harmonic currents, surge impact, harassment voltage electromagnetic compatibility test items. Electromagnetic compatibility (EMC) is an important factor affecting the reliability of LED lighting products.

1. EMC Test Standards:

There haven’t LED special standards focus on EMC test, the current practice is based on the field of LED lighting products, refer to the implementation of the relevant standards. Such as automotive LED lighting products should refer to CISPR25<Limits and test methods of protect vehicle receiver from radio disturbance characteristics>, ISO7637-2< Road vehicles – Transient conduction from conduction and coupling of electrical disturbances along supply lines> and ISO11452< EMI electromagnetic energy – Component test methods for road vehicles narrowband radiated> etc EMC standards, this article will not discuss them here. The point need discuss is general purpose LED lighting products (except automotive lighting, aircraft lighting, photocopiers and other special LED lighting equipment) EMC test standards, as shown in Table 1 below:

|

Standard No |

Standard name |

|

<Limits and test methods of radio disturbance characteristics of electrical lighting and similar equipment> |

|

|

IEC/EN 61547 |

<EMC immunity requirements of general lighting products> |

|

IEC/EN 61000-3-2 |

<Electromagnetic compatibility – Limits for harmonic current emissions (equipment input current ≤ 16A)> |

|

IEC/EN 61000-3-3 |

<Electromagnetic compatibility limits for voltage changes the rated current per phase ≤ 16A and unconditional access for equipment in public low-voltage power supply system, voltage fluctuations and flickers limits> |

2. EMC Test Item:

LED lighting product’s EMC test item included EMI and EMS. EMI mean electromagnetic interference, test LED lighting products may cause performance degradation or damage to generate electromagnetic disturbance of other things (including equipment, systems, people and animals and plants). EMS mean electromagnetic susceptibility( immunity test), test LED lighting product’s immunity ability for electromagnetic disturbances such as lightning, ESD static test and the fight against ringing waves immunity.

|

Main test content |

Main test equipment |

Test Environment |

|

|

Conducted disturbance |

9kHz~30MHz, QP/AV |

||

|

Harassment radiation (Magnetic induction current) |

9kHz~300MHz, QP |

||

|

Radiation Harassment (field) |

30MHz~300MHz, QP |

EMI receiver, CDNE, antenna |

Anechoic chamber |

|

EMS test item |

Main test content |

Main test equipment |

Test Environment |

|

Electrostatic discharge immunity |

Contact discharge±4kV, Air discharge±8kV |

No special requirement |

|

|

Electrical fast transient burst immunity |

Repetition rate 5kHz, Highest test level±1kV |

No special requirement |

|

|

Surge immunity |

1.2/50μs, Highest test level±2kV |

No special requirement |

|

|

Voltage dips short interruptions and voltage variations immunity |

0%UT, Duration of 0.5 cycles, 70%UT, Keep 10 cycles |

No special requirement |

|

|

Ring wave immunity |

Forefront of the open circuit voltage wave 0.5μs short circuit current wave frontier≤1μs oscillation frequency 100kHz±10% |

No special requirement |

The table 2 list EMC test items of LED lighting products which inlcuded main test intem, main test equipment, test environmental. The following will focus on the EMI test, electrostatic discharge and surge test.2.1. EMI Test:EMI(Electromagnetic Interference) included conducted interference and radiated interference. Conducted interference refers to the signal coupling through a conductive medium (interference) on an electric power network to another network; Radiated interference is the source of interference to its signal coupling through space (interference) to another radio network. In high-speed PCB and system design, the high-frequency signal line, the integrated circuit pins, various types of connectors so may become a source of interference with the antenna radiation characteristics, capable of emitting electromagnetic waves and affect other systems or to other subsystems within the system normal operation. As we know, the test object for EMC is electronic and electric device, among them, lighting is an important part which should do the EMC test naturally. Like FCC from America and CE from European Union, both of them request EMC measurement of LED lighting device. When talk about electromagnetic disturbance, generally it indicates two disturbance sources, one is conductive interference, it means that the disturbance signal will affect the EUT by conducting medium or public power supply; according to FCC, the LED lighting should do the conductive interference test at the frequency of 0.15MHz to 30MHz; but according to CE, it requests to do the test at the frequency of 9KHz to 30MHz. The other is radio disturbance, it means the disturbance signal will pass to electric network or device by the way of space coupling; according to FCC, the LED lighting should do the radio disturbance test at the frequency of 30MHz to 1GHz; but according to CE, it requests to do the test at the frequency of 30KHz to 300MHz.

In the lighting industry, when testing EMI frequency range at 9KHz~30MHz, there have two ways: The first is use Antenna and EMI Receiver which according to CISPR15, EN55015 and GB17743. For the low-frequency magnetic fields equipment which may produced by lighting luminaries, it need to adopt the provisions of tricyclic CISPR16-1-4 low frequency magnetic field antenna measurement radiation harassment. This need use three Loop Antenna and EMI receiver working together to measure it, and the testing must operate at inside of shielded room. Note: the three loop antenna made X direction, Y direction and Z direction’s low frequency magnetic field component converted to RF signal, and supplied to a receiver via three channels of EMI coaxial switch; The second way is use LISN, the testing system include EMI Receiver, Artificial Network Power, LISN and software. Conduction disturbance test system for measuring normal working lighting and lighting equipment’s harassmen which produced by power port. LISN achieve isolation RF signal, sampling, impedance matching, and provide electricity for EUT channel, EMI receiver for RF signal measurements and finally analyzed by EMI testing software, processing and sentenced limit. The testing must operate at inside of shielded room.

At the meantime, the testing EMI frequency range at 9KHz-300MHz will be use CDN. The CISPR15,EN55015 and GB17743 standards are also mentioned another way to measuring lighting equipment’s radiation harassment electric. that’s CDN common-mode terminal voltage method. The CDN test method include EMI Receiver, CDN and Attenuator, the testing can operate at inside of shielded room.

Base on CISPR16, Lisun Group developed two EMI test systems. According to the standards for traditional Lightings and new LED lightings, the frequency scanning range is different. The scanning frequency for EMI-9KB is 9 KHz to 300MHz, which is applied to LED and traditional lighting test; the scanning frequency for EMI-9KA is 9 KHz to 30MHz, which is applied to traditional lighting test. Both of them input three data to judge if the EUT can pass the test or not, that is PK, QP and AV. And user is freely to setup the standards (like GB17743, FCC, EN55015, GB4343) directly in the software.

2.2. Electrostatic Discharge Test:

LED is semiconductor device, under LED manufacturing, assembly, transportation, storage, production of equipment, materials and the operator all of these factors can bring static losses of LED which caused leakage current increases, the light fades increase, or even “dead lights” phenomenon. Electrostatic discharge will caused influence and damage for reverse leakage current, forward I-V characteristic and luminous flux of LED product. Electrostatic discharge is one of the important factors affecting the LED and LED lighting product reliability.

LED chip is key part of LED lighting product. For LED electrostatic discharge immunity testing should follow the relevant international standards such as the American National Standard ANSI / ESD STM5.1, ANSI / ESD STM5.2, the IEC(International Electrotechnical Commission) standard electronic JESD22-A114D, JESD22-A115-A, the US military Party standard MIL-STD-883 and so on. Lisun Electronic Shanghai office R & D designed and developed ESD61000-2 30KV Esd gun which is designed according to LEDs static-sensitive level and characteristics, it applied with Machine Model (MM) and Human Body Model (HBM) electrostatic discharge test, electrostatic discharge voltage maximum up 30KV; LED voltage and current measure accuracy can reach to 0.2%; LED forward voltage resolution 1mV; reverse leakage current resolution 0.01μA. For LED lighting product, it electrostatic discharge immunity test shall be in accordance with GB / T 17626.2 / IEC61000-4-2 conducted. Contact discharge is the preferred test method for each metal parts (excluding terminals) accessible on the cabinet LED lighting products for 20 consecutive discharge, polarity 10 times each. It can be use air contact discharge test if can’t use contact discharge test. Indirect discharges shall be applied to the horizontal or vertical coupling board in accordance with GB / T17626.2 of. To ensure consistency and repeatability of test results, electrostatic discharge test specification must be 7 chapters are arranged according to GB / T17626.2. If you interested in LISUN ESD simulator price, pls. contact us free. ESD61000-2 ESD simulator calibration data are as follows:

|

Output voltage(KV) |

First peak current |

30ns position current (A) |

60ns position current (A) |

Cutting edge (ns) |

|

2 |

7.29 |

4.10 |

2.20 |

0.93 |

|

4 |

15.40 |

7.90 |

4.30 |

0.97 |

|

6 |

23.20 |

12.10 |

6.50 |

0.97 |

|

8 |

29.40 |

16.20 |

9.30 |

0.89 |

|

-2 |

7.39 |

3.50 |

2.30 |

0.92 |

|

-4 |

15.50 |

7.70 |

4.30 |

0.89 |

|

-6 |

23.40 |

11.90 |

6.30 |

0.90 |

|

-8 |

31.80 |

16.10 |

8.20 |

0.90 |

Lightning is very common climate phenomenon, according to statistics, there are over 40,000 of the world thunderstorm centers, eight million lightning strikes a day, which means lightning about 100 times every second occurrence. Lightning struck near the ground or nearby objects which caused strong electromagnetic field around it, then induces a high voltage and high current on the line. On the other hand, the surge in the power system is a very common phenomenon. As the main power supply switch, short-circuit and arc fault or ground network grounding systems and so on.

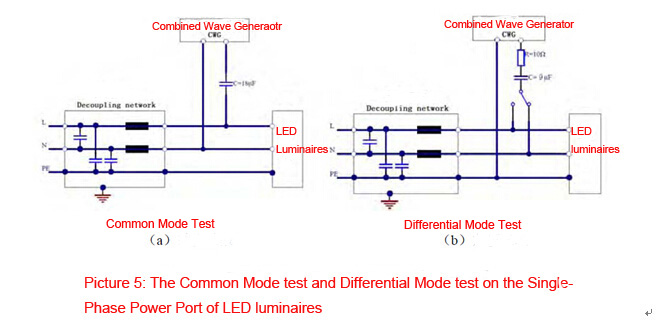

LED lighting products, especially for outdoor lighting products if without pay attention to lightning surge protection, it will seriously affect product reliability. A large area of LED lights in case of damage after thunderstorms common; According to quality supervision that there around have 60% LED lighting products can not meet lightning surges requirement. To assess the impact of LED lighting products, surge immunity performance shall be in accordance with EN/ IEC 61000-4-5 and GB / T 17625.5 requirements were surges testing. Test principle shown in Figure 5, the coupling network of common mode and differential mode test is different, differential mode test mean line – line test, the coupling capacitance is 18μF, it used to simulate the actual capacitance between the clouds and the earth; Common mode test mean line test – to earth test, the coupled network consist of capacitor and resistor network in series, the capacitor is 9μF and resistance is 10Ω.

Lisun Electronic Shanghai office R & D designed and devolped SG61000-5 Surge Generator which applied big LCD touch screen technology and it has built-in Windows CE operate syste. This surge generator can test maximum 12KV voltage output, the user can set up common mode test or differential mode test by themselves. Moreover, this device can automatic record the EUT test parameters after finished test, these parameters can give designer some reference.

Lisun Instruments Limited was found by LISUN GROUP in 2003.LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Surge Generator, EMC Test Systems, ESD Simulator, EMI Test Receiver, Electrical Safety Tester, Integrating Sphere, Temperature Chamber, Salt Spray Test, Environmental Test Chamber, LED Test Instruments, CFL Test Instruments, Spectroradiometer, Waterproof Test Equipment, Plug and Switch Testing, AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

Your email address will not be published. Required fields are marked *