Glossmeter is an instrument used to measure the surface glossiness of materials such as ceramics, paint, ink, plastic, marble, aluminum, and hardware. The high-precision glossmeter is divided into high gloss, medium gloss, and low gloss according to angle.

The glossmeter is manufactured in accordance with the ISO-2813 standard and is a high-precision, small glossmeter suitable for measuring mirror glossiness, such as paint, ink, plastic, stone, flooring, wooden furniture surfaces, etc.

The glossmeter is classified based on the angle of incidence. Generally speaking, the incident angle we choose during measurement directly affects the measurement result (glossiness value). The 60 degree incidence angle glossmeter commonly used by people does not have many restrictions, and can even be said to support the use of various materials.

working principle:

Glossiness is a physical quantity that evaluates the ability of a material’s surface to reflect light under a set of geometric conditions, with directional reflective properties. The gloss we usually refer to as’ mirror gloss’, so glossometers are sometimes also called ‘mirror glossometers’. The concept of “smoothness” or “roughness” in the gloss and machining industries is completely different, as the latter is a continuation of small surface irregularities in materials.

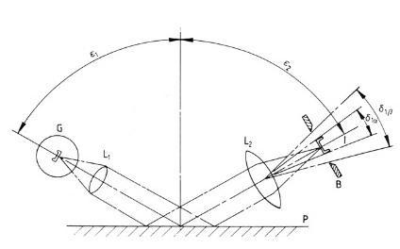

The measurement principle of the glossmeter is shown in the following figure. The measuring head of the instrument consists of a transmitter and a receiver, consisting of an incandescent light source and a set of lenses, generating a certain amount of incident beam. The receiver consists of a lens and a photosensitive element, which is used to receive a conical beam of light reflected from the surface of the sample.

Mirror glossiness is a relative measurement of mirror glossiness. The reference standard is black glass with a refractive index of np=1.567. Assuming that the plane reflects natural light beams in an ideal polished state, the gloss value at this point is defined as 100.0 gloss units. The glossiness board is divided into three types based on glossiness: high, medium, and low.

The high gloss plate is made of black optical glass or other materials. The medium and low gloss plate is made of glazed ceramic or black optical glass frosted. The glossmeter uses the principle of light reflection to measure the glossiness of the sample. Illuminate the sample at the specified incidence angle and beam to obtain the reflected light at the specular reflection angle.

Wave theory can qualitatively explain many optical properties of materials. According to wave theory, the ratio of the energy W entering the emitted light per unit time and the energy W of the reflected light per unit area can be derived.

Measurement Principle Of Glossmeter

Measurement techniques:

①. Please wait for a period of time from low temperature to high temperature (such as outdoor to indoor in winter). (Because there may be mist on the surface of optical lenses from low to high temperatures) Do not measure in direct sunlight to avoid affecting the measurement values.

②. When measuring curved objects with a small hole glossmeter, to ensure that the small hole is completely covered, the glossmeter measuring hole can slowly cover the measured object along the tangent of the measured surface until the light spot on the measured object (the white light spot on the measured object) is not visible.

Gloss meters AGM-580 are mainly used in the surface gloss measurement for paint, plastic, metal, ceramics, building materials. It conforms to the DIN67530, ISO2813, ASTM D523, JIS Z8741, BS 3900 Part D5, JJG696 standards and so on.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *