The potential and advantages of LEDs continue to develop. The next five to fifteen years will be a period of development of LED lighting from traditional (alternative) lighting to revolutionary (humanized) lighting. The industry should pay attention to the trend of standards and meet the development of new industries. Opportunities and Challenges. In the standardization activities of our country, from the early tracking and equivalent adoption of standards, and the active participation in the formulation of standards since the beginning of this century, it has begun to lead some standards today. After the turmoil of the financial crisis, China’s position on the stage is undergoing new changes, and our country’s right to speak in semiconductor lighting standards is also increasing, which will have an important impact on country’s future trade. Our country has made significant progress in semiconductor lighting inspection technology and equipment, and its status in the industry has been increasing. Especially in the formulation of LED inspection technology standards, our country’s leading position in some key standards has been affirmed.

In terms of LED detection technology, the characteristics of LED products are quite different from traditional light sources. The luminescence of LEDs is closely related to the junction temperature. In the optical and optoelectronic parameter testing of LED products, changes in ambient temperature, heat sink or case temperature will change the junction temperature of the LED, thereby affecting the light output. In the photometric test of LED lamps, the light-emitting device and the lamp shell are often inseparable, and an integrated test is required, usually by photometric measurement. The blue light of some high-brightness LEDs can cause photochemical damage to the retina of the human eye. According to the IEC62471 “Photobiological Safety of Lamps and Lamp Systems” series of standards, the test of the photochemical damage of LED products is also one of the hot spots that the industry is concerned about. In addition, LED products have the characteristics of long life, and we cannot carry out long-term ignition test like ordinary lighting products. Certain accelerated test methods must be used to predict the effective life of LED products. For example, the US “Energy Star” adopts the LM-80 standard, and my country LED life accelerated test method standard under development.

Therefore, in recent years, LED product performance measurement technology and testing equipment have developed rapidly. In our country, with the rapid development of the LED industry, the innovation ability of testing technology and equipment has been significantly improved, and a series of advanced testing equipment has been launched to meet the urgent needs of the current industry; especially in the optical and energy efficiency testing of LED products, and the spatial light distribution measurement of lamps , accelerated test detection of life, photobiological radiation safety detection, etc., developed competitive advanced detection equipment.

1. Optical and energy efficiency testing of LED products

In the performance test of LED products, temperature control is very important. According to relevant standards at home and abroad, LED devices generally control the junction temperature or housing hot spot temperature. For LED modules, control the hot spot temperature on the heat sink of the module. And for LED application products, the ambient temperature is used as the benchmark. Therefore, in the optical and energy efficiency testing of LED products, for LED devices, modules and application products, the temperature control method in the test equipment is very important.

The beam directivity of some LED products is relatively strong. When measuring in the integrating sphere, the beam projection area and the position of the screen are relatively sensitive. Both the IESNALM79 standard and the CIE127 technical report have stipulated that it is recommended to use a sphere with a higher spectral reflectance. Inner wall coating material. NIST in the United States is at the forefront of the world in promoting LED standard test methods and standards, and it also puts forward extremely high requirements for test equipment.

2. LED life accelerated test

The life of LED products can reach tens of thousands of hours. The LED industry is very concerned about how to evaluate the life of products. A feasible method is an accelerated thermal stress test based on the operating temperature of the LED junction. The American LM-80 standard specifies three test temperatures: 85°C, 55°C and custom (25°C) to obtain the light decay curves of LEDs at several temperatures, and the test time is 6000 hours. The LED life accelerated test standard being drafted in my country does not specify the test temperature. Generally, the accelerated test thermal stress needs to be selected according to the characteristics of the LED structural material. Figure 6 is an accelerated test device for LED life and reliability independently developed by my country, which can conduct tests in three temperature zones at the same time, and each temperature zone can conduct tests on 30 samples. The detection system detects in real time the decay curve of the light intensity and chromaticity coordinates of each test LED sample under the specified electrical parameters (forward current) with time. At the same time, the junction temperature (case temperature) and the electrical parameters in the test are recorded in real time, and the parameters such as the effective life of the LED are automatically given.

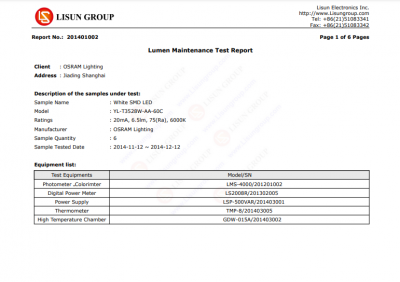

LEDLM-80PL LED Lumen Maintenance and Aging Life Test System is designed according to IES-LM-80 and TM-21, it used to test & record the optical and electrical Maintenance for single LED or LED module, the software is based on Arrhenius model and TM-21 to calculate the LED life. The LEDLM-80PL needs to work with a GDJW/GW Series High Temperature Chamber and and DC12010 DC Power Source.Test report as below and you can also click here to see one of the test report sample of LEDLM-80PL (The LEDLM-84PL report is similar but only difference is based on TM-28).

Lumen Maintenance Test Report

LEDLM-84PL LED Lumen Maintenance and Aging Life Test System is designed according to IES LM-84 and TM-28, it used to test & record the optical and electrical Maintenance for LED luminaires, the software is based on Arrhenius model and TM-28 to calculate the LED life. The LEDLM-84PL needs to work with a GDJW/GW Series High Temperature Chamber and and LSP-1KVARC AC Power Source.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *