Ultraviolet sterilization is a traditional and effective disinfection method. It has been widely used in hospitals, food factories, water treatment, etc. However, it is affected by many factors during the use process, especially the low radiation intensity of the lamp and improper application Disinfection effect. In order to ensure a satisfactory disinfection effect, we have mainly implemented the following monitoring and management measures during use.

How to use ultraviolet germicidal lamp:

1.When using ultraviolet germicidal lamps, people and animals must leave the scene.

2. Eyes should not look directly at the lights for a long time. The operation of ultraviolet rays is very simple. Turn on the power and leave the room.

3. Close the door, operate the remote control, select the sterilization time, and press the start button.

4. Choose the sterilization time as needed, press the switch start button, and the ultraviolet sterilization lamp will automatically turn on after 10 seconds.

Ultraviolet radiation intensity is the most basic factor that affects the disinfection effect. According to the requirements of the “Disinfection Technical Specification”, the radiation intensity of the new ultraviolet lamp should be greater than 100μW / cm2 (at a distance of 1m),The minimum radiation intensity of the lamp in use should reach 70μW / cm2, but the irradiation time must be extended. According to the formula of ultraviolet radiation dose equal to radiation intensity multiplied by irradiation time, the prolonged irradiation time required for different intensities can be obtained. It can also be seen that high intensity short time or low intensity long time can obtain the same sterilization effect. If the intensity of the ultraviolet light source is lower than 40μW / cm2, then the irradiation time can not be extended to achieve a satisfactory sterilization effect, that is, it should be stopped. Don’t think that as long as the UV lamp is on, it still has a sterilizing effect.

According to the second volume of the “Disinfection Technical Specification”, 3rd Edition (Hospital Disinfection Specification) issued by the Ministry of Health, the number of indoor suspended ultraviolet disinfection lamps (30W ultraviolet lamps, the radiation intensity at 1m vertical is higher than 70μW / cm2) It is not less than 1.5W per cubic meter on average, and requires uniform distribution, and the lifting height is 1.8 to 2.2m above the ground, so that the human breathing zone is in the effective irradiation range. Continuous irradiation for no less than 30 minutes, the intensity of ultraviolet radiation is inversely proportional to the radiation distance, the suspension is too high, affecting the sterilization effect. If the surface of the object is sterilized, the distance between the lamp and the irradiated surface should be 1m, and sterilization is effective.

The ambient temperature has a certain influence on the ultraviolet radiation intensity. The temperature is too high or too low will reduce the radiation intensity, such as when the temperature drops to 4 ℃, the radiation intensity can be reduced by about 65% ~ 80%, seriously affecting the sterilization effect. Generally, the room temperature is 20-40 ℃ as the suitable temperature for ultraviolet sterilization. Within this temperature range, the intensity of ultraviolet radiation is the largest and stable, which can achieve the ideal disinfection effect.

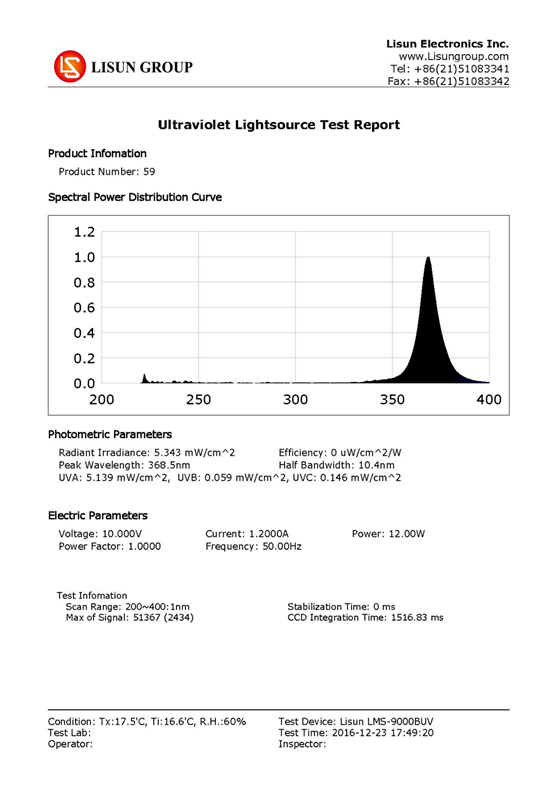

In summary, the radiation intensity of the ultraviolet sterilization lamp is a very important parameter for the sterilization and disinfection effect. LISUN LPCE-2(LMS-9000BUV) UV Lamp Test System is used to test the UV lamp (light source) Spectrum, Radiant, Efficiency, CRI, CCT, UVA, UVB, UVC radiant and electric parameters.Spectral Range Wavelength: 200-400nm(UV). The whole system includes the LMS-9000BUV High Precision UV Spectroradiometer,CFS-1.2M Silica Fiber,CASE-UV036 Dark Case for UV Test ,SLS-UV UV Standard Light Source with Calibrate Current (Optional).

Here is photo below shows the test system:

The following is the test report of this product for your reference:

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Surge Generator, EMC Test Systems, ESD Simulator, EMI Test Receiver, Electrical Safety Tester, Integrating Sphere, Temperature Chamber, Salt Spray Test, Environmental Test Chamber, LED Test Instruments, CFL Test Instruments, Spectroradiometer, Waterproof Test Equipment, Plug and Switch Testing, AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp: +8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp: +8618917996096

Your email address will not be published. Required fields are marked *