Electromagnetic interference (EMI) is a phenomenon that may occur when an electronic device is exposed to an electromagnetic (EM) field. Any device that has electronic circuitry can be susceptible to EMI.

The widely application and development of electronic devices will inevitably lead to the continuous increase in electromagnetic field levels generated in their surrounding spaces. In 1881, British scientist Shivisid published an article on “Amboction”, which has begun to start the prelude to the research of electromagnetic interference. From June 28th to 30th, 1934, the International Radio Interference Special Committee (CISPR) held the first formal meeting in Paris, and since then, electromagnetic interference and its control technology have organized organizational research. The various standards of CISPR have become an important basis for the provisions of electromagnetic interference indicators in various countries around the world.

Electromagnetic interference needs to be paid attention to

Recently, a mobile phone brand announced that its latest product series and accessories will interfere with medical equipment. Therefore, it is recommended that medical implantation equipment carriers away from the phone more than 15 cm away from the heart.

To this day, the problem of electromagnetic interference is always a focus that electronic equipment needs to pay attention to. Not only in consumer electronics, it is even more so in the application of automotive, industry and other applications with more complicated electromagnetic environment. Such EMI are often inside the circuit, and EMI will eventually affect audio equipment, automatic door controllers, and other intentions unexpected results.

Most electronic equipment will have periodic or intermittent voltage current changes when working. For example, there will be a fixed switching frequency of switching power. (DI/DT), which brings very rich harmonics; in addition to the AC-DC, DC-DC switching power supply applied to various occasions, there are also some inverters (photovoltaic, motor control, etc.) PWM signals is the source of interference caused by EMI. In addition, print circuit boards, clock circuits, oscillators, digital circuits and processors will also become an EMI source inside the circuit. For some electromechanical devices that perform switch operations, EMI will be generated during critical operations. These sources produce some electromagnetic energy concentrated in some frequencies, and are transmitted into the surrounding environment through the corresponding circuit, antenna or an equivalent antenna. The spectrum composition and strength of these EMI signals determine whether it will affect sensitive circuits.

The impact of EMI has become a key consideration for system design, but for some engineers, it does not put it in the first consideration of the design process, and it will only be tested when it is required. In this regard, the general manager of LISUN Technology analyzed: “One of the reasons is that EMI is not defined as a key specification indicator of the system during design. Let’s predict EMI, which only causes the problem of EMI in later testing.

“One of the reasons is that EMI is not defined as a key specification indicator of the system during design. Discover the problem of EMI.

When an engineer finds the problem in the later period, it may be more difficult to solve the EMI problem and consume a lot of time and capital costs. In fact, the rectification of EMI is extremely cumbersome. Many small and medium -sized companies do not have such conditions themselves. Most of them must choose third -party to rectify. It will be a small expense. In view of EMI, the design progress may be severely hindered in the later period, so the EMI problem must be considered at the beginning of the design and its indicators penetrate the entire product design cycle.

How to solve the EMI problem

For some electromagnetic sensitive equipment or systems, LDO is usually used instead of switching power supply, which limits EMI, but this will cause adverse effects such as decreased efficiency. Is there any solution to the EMI problem significantly, and there is no need for too much additional design overhead. At the same time, it can be used to use the solution to the power supply power supply?

“The key to solving EMI -related problems is to start with the source.”

EMI has brought huge challenges to the design of the engineer, but factors such as the limitation of the circuit board layout and the additional design of the design do not mean that the engineer has no other choice. In fact, the chip with EMI relieving technology can actually improve EMI from the source. This is also mentioned by the media’s recent interview engineers. Their most commonly used means to reduce EMI is to choose low EMI devices and coincide.

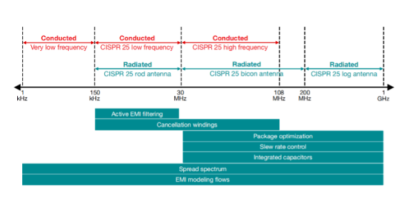

There are many forms of EMI issues, depending on the influential band. In order to effectively alleviate the EMI problem, LISUN EMI testing equipment uses a set of comprehensive technologies, that is, unique IC design and packaging technology, which can solve the main source of EMI according to a specific frequency band. This helps to avoid a one -size -fits -all -knife -cut solution on other frequency bands.

In addition, in order to solve the problem from the source, engineers must have good simulation and modeling methods to predict EMI when designing. LISUN’s unique EMI testing equipment enable engineers to design power converters with excellent EMI performance like designing high -efficiency and high power density performance.

LISUN specifically introduces the comprehensive technology of EMI, as shown in the figure:

EMI Comprehensive Technology

The EMI problem is decomposed into a specific frequency band (low -frequency and high frequency), and every EMI problem of these specific frequencies can be solved more targeted.

For low -frequency problems (<30 MHz), the power converter of LISUN uses advanced frequencies and active filtering technology to reduce the passive filter burden required on PCB to meet and surpass the standards. This helps the terminal system becomes smaller and lower, while meeting its EMI needs.

For problems related to the high frequency (FM frequency > 100 MHz band), LISUN’s power converter uses various gate drivers, packaging and passive integration technology to minimize EMI problems from the source. This helps to solve some difficult grounding and shielding problems that usually need to be debugged in traditional systems.

Due to the interaction between IC, component and PCB design, “even after the EMI is solved from the source, the system engineer needs to consider the appropriate EMI indicator when assembling terminal devices to better play the system’s function.

Integrated active filter and dual random frequency expansion technology

LISUN provides multiple functions and technologies to reduce EMI in all related frequency bands. Their innovative technical advantages are mainly manifested:

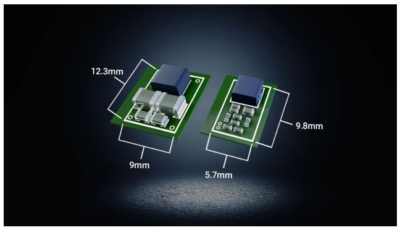

• Improved filter size and cost: Advanced frequency expansion and active EMI suppression technology can reduce the impact of EMI generated;

• Reduce design time and reduce design complexity: Crystal packaging, capacitor integration, and advanced grille driver technology can fundamentally reduce the noise generated by the source.

Integrated active filter and dual random frequency expansion technology

In addition, LISUN EMI-9KC EMI test receiver uses dual random spreading technology to combine low-frequency triangle modulation with high-frequency pseudo-random modulation to improve the EMI performance of low-frequency and high-frequency bands, respectively. In addition to the significant advantages in EMI, this product has excellent performance in the performance indicators such as adjustment rates, efficiency, temperature rise, and ripples.

In addition, LISUN provides various combinations for different application scenarios and different EMI scenes, so that engineers can improve EMI more targeted.

Summarize

“EMI is a tricky issue in some designs, such as in automotive systems, such as information entertainment, electronics, ADAS, etc. When designing schemes and drawing maps, engineers need to be vigilant at any time.

In addition to the rapid development of automotive electronics, the rapid development of industry and personal computing applications, the demand for faster listing, more cost -effectiveness, and smaller -sized electronic products will also increase, which will inevitably make new challenges to EMI. A variety of advanced EMI relief technology is required to ensure that the product design is smoothly tested through the industry’s general EMI.

Engineers should prepare to deal with EMI challenges. For engineers who do not often deal with EMI issues, we must also understand the composition of EMI and the method and reasons for EMI, and to fully understand the various standards that terminal equipment manufacturers need to meet.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *