Two types of photometry are used: spectrophotometer and goniophotometer. The optical characteristics detection of LED mainly includes: luminous intensity test, luminous flux test, spectral characteristics test (chromaticity coordinate correlated color temperature, color rendering index, dominant wavelength), spatial light intensity distribution test, and the influence of temperature effect on LED optical characteristics. Screens generally also require surface brightness detection. Due to the particularity of LED light sources compared to traditional light sources. The corresponding LED test instruments for the detection of LED optical properties have also been gradually developed and improved now.

1. Luminescence intensity test

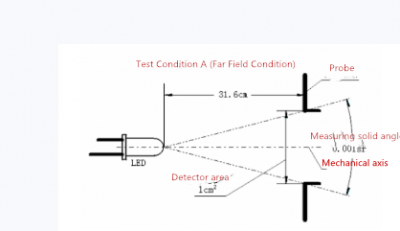

The luminous intensity detection of traditional light sources generally follows the inverse square law of the distance of the point light source, that is, an isotropic point light source S with a luminous intensity of I emits light radiation to a surface with an area of dS, its distance is r, and its surface illuminance E=I /r2, so the luminous intensity of the light source can be obtained by measuring the illuminance at a certain distance. However, due to the different shapes of LEDs, it can be found by tracing the LED rays that the light emitted by each area of the LED has different focal points, so the LED cannot be described as a point light source, which brings difficulties to the measurement of luminous intensity. Therefore, the CIE127 document stipulates the measurement of LED luminous intensity, which is divided into two conditions, A and B.

Test condition A

Test condition B

The A and B measurement conditions are not strictly measured according to the definition of luminous intensity, therefore, they are called “average luminous intensity”. At present, most laboratories in the world have agreed to use A and B measurement conditions.

LISUN LSG-1890B/LSG-1800A goniophotometer is automatic goniophotometric instrument for luminous intensity distribution measurements with facility for rotating the light source. The LSG-1890B/LSG-1800A uses a constant temperature detector, Japanese motor and German precision angle coder which keep the test results with high accuracy. It is for industrial laboratory photometric data measurement of all kinds of luminaries such as LED luminaries, HID lamps, fluorescent lamps and so on.

Measurement:

Luminous Intensity Data, Luminous Intensity Distribution, Zonal Luminous Flux, Luminaries Efficiency,Luminance Distribution,Coefficient Of Utilization, Luminance Limitation Curves Glare, Maximum Ratio of Distance to Height, Equal Illuminance Diagrams, Curves of Luminaires VS Lighting Area, Isocandela Diagrams, Efficient Luminescence Angle, EEI, UGR, etc.

Standard:

Full meet the EN13032-1 clause 6.1.1.3 goniophotometer type 1, COMMISSION DELEGATED REGULATION (EU) 2019/2015, CIE-70, CIE-121, IES LM-79, IES LM-75, IES LM-80 and ect.

High Precision Rotation Luminaire Goniophotometer LSG 1890B

2. Luminous flux test

LISUN LSG-1800A/LSG-1890B goniophotometer can accurately measure the total luminous flux of LED (under the condition that the spectral response curve of the detector has been corrected), which is the absolute measurement method of the total luminous flux of LED, which requires customers to have enough budget. Of course, if the customer is limited, LISUN LPCE-2 High Precision Spectroradiometer Integrating Sphere System can also test the luminous flux. Integrating spheres are commonly used for measurement in general industry.

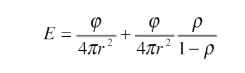

The illuminance E of any point B in the integrating sphere consists of two parts: the illuminance Ed directly illuminated by the light source C on point B and the illuminance Ei generated by multiple diffuse reflections on the sphere wall.

Integrating sphere test principle:

Standard lamp calibration, the measured light flux data (relative measurement) is obtained through the coefficient.

Integrating sphere test method:

Spectroscopy: Optical fiber measurement (obtain chromaticity coordinates (x/y, u/v), and calculate other color parameters;

Photometry: Probe V(λ) correction measurement.

Integrating sphere test method: 4π (integrating sphere center test); 2π (integrating sphere side opening test, more difficult: it is difficult to fix the test lamp, light leakage, standard lamp calibration method. Generally, it is a 4π measurement method.

LISUN LPCE-2 Integrating Sphere Spectroradiometer LED Testing System is for single LEDs and LED lighting products light measurement. LED’s quality should be tested by checking its photometric, colorimetric and electrical parameters. According to CIE 177, CIE84, CIE-13.3, IES LM-79-19, Optical-Engineering-49-3-033602, COMMISSION DELEGATED REGULATION (EU) 2019/2015, IESNA LM-63-2 and ANSI-C78.377, it recommends to using an array spectroradiometer with an integrating sphere to test SSL products. The LPCE-2 system is applied with LMS-9000C High Precision CCD Spectroradiometer or LMS-9500C Scientific Grade CCD Spectroradiometer, and A molding integrating sphere with holder base. This sphere is more round and the test result is more accruacy than the traditional integrating sphere.

High Precision Spectroradiometer Integrating Sphere System

Measures:

• Colorimetric: Chromaticity coordinates, CCT, Color Ratio, Peak Wavelength, Half Bandwidth, Dominant Wavelength, Color Purity, CRI, CQS, TM-30 (Rf, Rg), Spectrum Test

• Photometric: Luminous Flux, Luminous Efficiency, Radiant Power, EEI, Energy Efficiency Class, Pupil Flux, Pupil Flux Efficiency, Pupil Factor, Cirtopic Flux, Plant Growth Lamp PAR and PPF

• Electrical: Voltage, Current, Power, Power Factor, Displacement Factor, Harmonic

• LED optical maintenance test: Flux VS time, CCT VS time, CRI VS time, Power VS time, Power Factor VS time, Current VS time and Flux Efficiency VS time.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *