Product No: HCAI-2

HCAI-2 Large Arc Ignition Test System is according to IEC 61800-5-1:2022 Clause 5.2.5.2 Figure 26, IEC 60947-1:2020 Annex M Figure M.2 (GB/T 14048.1-2023 Appendix M Figure M.2), IEC 60730:2022 Annex D.1.10( GB 14536.1-2022 Appendix D.1.10), IEC 60950-1:2020 ( GB 4943.1-2022) , BS 7002:2000, and UL 746A:2021. It is mainly used in the parts of insulating materials or other solid combustible materials that are easy to spread flames inside electrical and electronic equipment. They may ignite due to proximity or contact with electric arcs, causing electrical fires and endangering the reliable operation of equipment and personal safety. This test system is suitable for the research, production and quality inspection departments of electrical and electronic products and their components such as lighting equipment, low-voltage electrical appliances, household appliances, machine tool electrical appliances, motors, power tools, electronic instruments, electrical instruments, information technology equipment, electrical business equipment, electrical connectors and accessories, and is also suitable for the insulation material, engineering plastics or other solid combustible material industries.

Standard:

IEC 60950-1:2020 “Information technology equipment – Safety – Part 1: General requirements”

BS EN 60950-1:2020 “Information technology equipment – Safety – Part 1: General requirements”

BS 7002:2000 “Specification for Safety of Information Technology Equipment Including Electrical Business Equipment”

UL 746A:2021 “UL Standard for Safety Polymeric Materials – Short Term Property Evaluations”

IEC 60947.1: 2020 “Low-voltage switchgear and controlgear – Part 1: General rules”

IEC 730.1:1993

GB 4943.1-2022 “Safety of Information Technology Equipment”

IEC 60664-1:2020 “Insulation coordination for equipment within low-voltage supply systems – Part 1: Principles, requirements and tests”

Test principle:

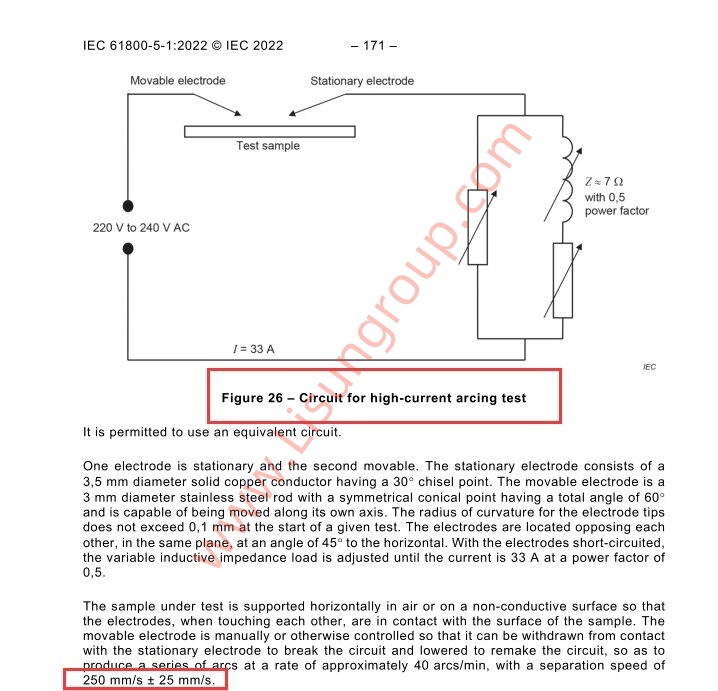

The arc ignition is repeated on the surface of the sample to 200 times, and the high current arc ignition resistance performance of the sample is evaluated by whether the sample ignites under the specified number of arc ignition.

System Configuration:

• Screen: 7-inch touch screen.

• Control System: PLC.

• 40A Power Meter: Real-time display of current, voltage, power, frequency, power factor, and with alarm function.

• Test voltage, current and power factor are adjustable.

• Equipped with a fan exhaust system, built-in LED lighting, and all electrical parts adopt world-renowned brands such as Schneider.

Specification:

• Electrode materials: copper (electrostatic electrode), stainless steel (movable electrode);

• Electrode size: ф3.2mm~ф3.5mm 30° chisel end (static electrode), ф3.0mm 60° cone end (moving electrode);

• Electrode angle: 45° from the horizontal plane;

• Arcing current: 33±5%A (Adjustable);

• Arcing power factor: COSφ0.5±0.05 (Adjustable);

• Arcing speed: 250mm/s ± 25mm/s;

• Arc ignition frequency: 40 times/min (Adjustable);

• Number of arcs: 200 times (Can preset);

• Sample size: 130mm*13mm*(2~12)mm;

• Power Supply: 220V/10kVA/50Hz

Operation:

Set the test times, test speed, and loading current on the touch screen. Click “Start Test” after adjusting the power factor to 0.5. The test will be automatically performed according to the set requirements. After the test is completed, the test power will be automatically cut off and a buzzer alarm will sound.

IEC 61800-5-1:2022 Clause 5.2.5.2 Figure 26