Product No: SUG255

Impulse Voltage Generators | Impulse Generators | Impulse Withstand Voltage Tester |High Voltage Surge Generator is according to IEC255-5, GB-14711 , GB/T-14598.3, IS-13252-1, IEC60060, IEC60065, GBT17215.301 and GBT17215.322. The insulation performance test is suitable for all kinds of electrical and electronic products (such as energy meter, household appliances, low voltage electrical appliances and small power motors).

Standard:

IEC255-5 “Relays – Insulation tests”

IS-13252-1 “Information technology equipment — Safety Part 1 General requirements”

IEC60060 “IEC 60060-1-2010 High-voltage test techniques – Part 1 General definitions and test requirements”

IEC60065 ” Audio, video and similar electronic apparatus – Safety-requirements”

IEC 60255-5:2000/GB/T-14598.3″Electrical relays – Part 25: Electromagnetic emission tests for measuring relays and protection equipment”

GB/T-3048.8 “Test methods for determining electrical properties of electric cables and wires.A.C. voltage tests”

| LISUN Model | SUG255LX | SUG255MX | SUG255PX | SUG255PX-20KV | SUG255PX-25KV | SUG255PX-30KV |

| Range of Output Voltage | 0~12kV | 0~20kV | 0~25kV | 0~30kV | ||

| Impedance of Generator | 12Ω and 500Ω | 38Ω and 500Ω | 2Ω and 500Ω | |||

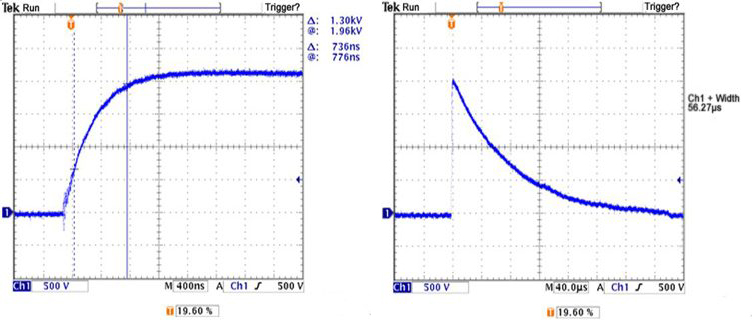

| Voltage Output Waveform | 1.2 / 50μs | |||||

| Polarity of Output Voltage | Positive and Negative | |||||

| Operation Mode | Manually and Automatic | |||||

| Test Repetition | 1~9999 | |||||

| Interval Time | 3~9999s | |||||

Waveform: