Product No: EDX-4

On June 4, 2015, the Official Journal of the European Union (OJ) issued the RoHS 2.0 revised directive (EU) 2015/863. Based on the original six substances restricted by RoHS (lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyls, and polybrominated diphenyl ethers), four phthalates were added to the list of restricted substances under RoHS 2.0, and it has been compulsorily implemented since July 22, 2019. LISUN has developed the EDX-4 RoHS 2.0 testing system, which is based on the solution for rapid screening of phthalates through pyrolysis desorption. It is specifically designed for the testing of the following four hazardous substances:

|

Substance Name |

CAS NO. |

Main Applications in Electrical and Electronic Equipment |

|

Bis(2-ethylhexyl) Phthalate (DEHP) |

117-81-7 |

It is mainly used as a plasticizer for PVC. PVC is used as an insulator in electrical and electronic equipment, such as cables and wires. A small amount of DEHP is used for other non-polymer applications, such as the electrolyte of ceramics or capacitors in electronic products. |

|

Butyl benzyl Phthalate (BBP) |

85-68-7 |

It is mainly used in combination with other plasticizers in PVC components such as cables, sockets, pipes, and shock absorbers. In addition, it is also used in some non-polymers such as paints and glues. |

|

Dibutyl Phthalate (DBP) |

84-74-2 |

It is mainly used as a plasticizer in PVC flooring. In electrical and electronic equipment, it may be present in synthetic leather, textile coatings, PVC materials, printing inks, sealants, and glues. |

|

Diisobutyl Phthalate (DIBP) |

84-69-5 |

It is used as a plasticizer for PVC, and can be used as a substitute for DBP. It can also be used as a plasticizer for cellulose resins, vinyl resins, nitrile butadiene rubber, and chloroprene rubber. |

Part 1: Product Features

• No chemical pretreatment required: There is no need for ultrasonic extraction or extraction with chemical reagents. Samples can be directly injected in solid or liquid form, and the operation is simple. Short sample testing time: The sample testing time of 20 minutes per sample fully meets the rapid detection needs of corporate users.

• No environmental impact assessment required, and no professional laboratory needed: Without the need for reagents or pretreatment, no waste gas or liquid is generated, so there is no need to apply for an environmental impact assessment.

• 100% sample applicability: Chemical methods are only suitable for soluble polymer samples (applicable to 70% of samples), while this method is applicable to soluble, hardly soluble, and insoluble polymer samples (applicable to 100% of samples).

• No professional laboratory environment required: It only requires an ordinary operating space equipped with an air conditioner, power supply, operating table, nitrogen, and a refrigerator to be installed and used.

Part 2: System Composition (The EDX-4 RoHS 2.0 Testing System is composed of the following equipment)

|

Product Name |

Specification Model |

Quantity |

Remarks |

|

A. Pyrolysis Desorption Instrument |

• Pyrolysis desorption instrument with pyrolysis and thermal desorption functions, equipped with a ceramic heating module. • Equipped with a user-defined ascending temperature function and a nickel-cobalt temperature sensor. • Equipped with PC-side operation software and system status monitoring software, and full solenoid valve gas circuit control. • Equipped with a deactivation and inerting system. |

1SET |

EDG version |

|

B. Gas Chromatograph |

D. Equipped with an FID (Flame Ionization Detector) + E. Capillary Sampling System + SSL (Split/Splitless Injection Port) |

1SET |

FID |

|

C. Special Chromatographic Column |

Imported 15-meter special chromatographic column |

1SET |

Capable of detecting 4 phthalates simultaneously |

|

Workstation |

The chromatographic workstation can generate test reports with one click |

1SET |

|

|

Electronic Balance |

Switzerland Precisa 1/10000 balance |

1SET |

|

|

4Kinds of Phthalate Standards |

• 4 bottles of 1000ppm mixed standards of 4 kinds of phthalate samples, 1ML each. • 4 glass bottles + 4 Teflon caps. • 1 1ml solvent bottle, 1 piece of Teflon sealing film. |

1SET |

Standard substances |

|

Consumables |

• 100 quartz injection tubes. • 2 quartz injection sleeves (liner tubes), 1 portion of quartz wool. • 1 beaker. • 1 pack (50 pairs) of medical nitrile gloves, 1 pack of weighing paper. • 1 bottle of n-hexane. • 1 sample cutting knife. |

1SET |

Consumables |

|

High-purity Hydrogen Generator |

Hydrogen: 0-300ml/min, 0.3MPa |

1SET |

|

|

High-purity Air Generator |

Air: 0-2000ml/min, 0.45MPa |

1SET |

|

|

Nitrogen Cylinder |

Purity of 99.999%, equipped with a pressure reducing valve |

1SET |

Provided by the user |

|

Standard Refrigerator |

For storing standard samples |

1SET |

Provided by the user |

|

Computer |

Desktop commercial computer |

1SET |

|

Part 3: Specifications

A. Specification of the Pyrolysis Desorption Instrument:

• Temperature range of the pyrolysis device (Φ6 pyrolysis tube): Room temperature to 450°C, which can be set arbitrarily in increments of 1°C. Heating rate of the pyrolysis device (Φ6 pyrolysis tube): > 500°C per minute.

• Pyrolysis time range of the pyrolysis device: 0.01 to 99.99 minutes, which can be set arbitrarily in increments of 0.01 minute. Purge time range of the pyrolysis device: 0.01 to 99.99 minutes, which can be set arbitrarily in increments of 0.01 minute. Purge flow range of the pyrolysis device: 10 ml to 200 ml.

• Split flow range of the pyrolysis device: 10 ml to 200 ml.

• Heating control voltage of the pyrolysis device: 16 VDC.

• Temperature range of the aging and cleaning device: Room temperature to 450°C, which can be set arbitrarily in increments of 1°C (optional).

• Time range of the aging and cleaning device: 1 to 1200 minutes, which can be set arbitrarily in increments of 1 minute.

B. Specification of the Gas Chromatograph:

• The split/splitless injection system makes the analysis flexible and convenient.

• It comes with a two-way valve control system, which facilitates online automatic injection.

• The high-precision gas control system makes the gas flow clear at a glance, allowing for more accurate setting of the gas flow rate.

• The comprehensive detection and fault diagnosis system enables you to quickly identify and solve problems occurring in the instrument.

• A wider temperature control range: ambient temperature + 5°C to 400°C, expanding the range of sample analysis.

• The unique gas cut-off protection system can, to the greatest extent, prevent the detector and the chromatographic column from being damaged.

• The column oven can be equipped with an ultra-low temperature control system. The ultra-low temperature control down to -80°C can meet your needs for analyzing substances with low boiling points.

• The inter-column compensation circuit provides electronic compensation for the baseline drift during the programmed temperature rise operation, reducing the complexity brought about by the second column, detector, and auxiliary flow system. Two single-column compensation channels can be installed simultaneously.

C. Specification of the Special Chromatographic Column:

• Temperature range: Ambient temperature + 5°C to 450°C.

• Three – stage programmed temperature rise, with a heating rate of 0 – 50°C/min and an increment of 0.1°C/min. The temperature control accuracy is ±0.015°C.

• Users can recalibrate the oven temperature and freely set the maximum temperature. The intelligent rear – door opening system has a steplessly variable air intake and exhaust volume, which shortens the system stabilization time after heating or cooling. The time taken for the column oven to cool from 300°C to 50°C is less than 12 minutes.

D. Specification of the Flame Ionization Detector (FID):

• It is easy to disassemble and install, facilitating the cleaning or replacement of the nozzle, and the operation is simple.

• The input signal can be logarithmically amplified, reducing interference. It has high sensitivity, good linearity, and a wide measurement range.

• Detection limit: Mt ≤ 5×10⁻¹²g/s (n-hexadecane); Baseline noise: ≤ 6×10⁻¹²A/H; Linearity range: ≥ 10⁵.

• Stabilization time: < 0.5h.

E. Specification of the Sampling System:

• Packed Column Injector: It is suitable for various diameters of packed columns and large-bore capillary columns.

• Capillary Injector: A split/splitless injection system controlled by a programmable valve can be optionally installed

Part 4: Pretreatment Process

This method does not require pretreatment. The consumables include a 2.5-cm-long quartz tube, quartz wool, and a pretreatment column. Place the solid sample in the middle of the quartz tube, fix both ends with quartz wool, and then put the prepared sample tube into the heating chamber.

Part 5: Analysis Conditions:

• Programmed temperature rise for pyrolysis: 200°C – 450°C

• Micro-pyrolysis time: 2 minutes

• Sampling method: Split injection

• Liquid injection volume: 1 μl

• Solid injection volume: Less than 5 mg

• Injection port temperature: 250°C

• FID detector temperature: 300°C

• Programmed temperature rise: 50°C (held for 1 minute), then increased to 450°C at a rate of 20°C per minute (keep for 4 minutes)

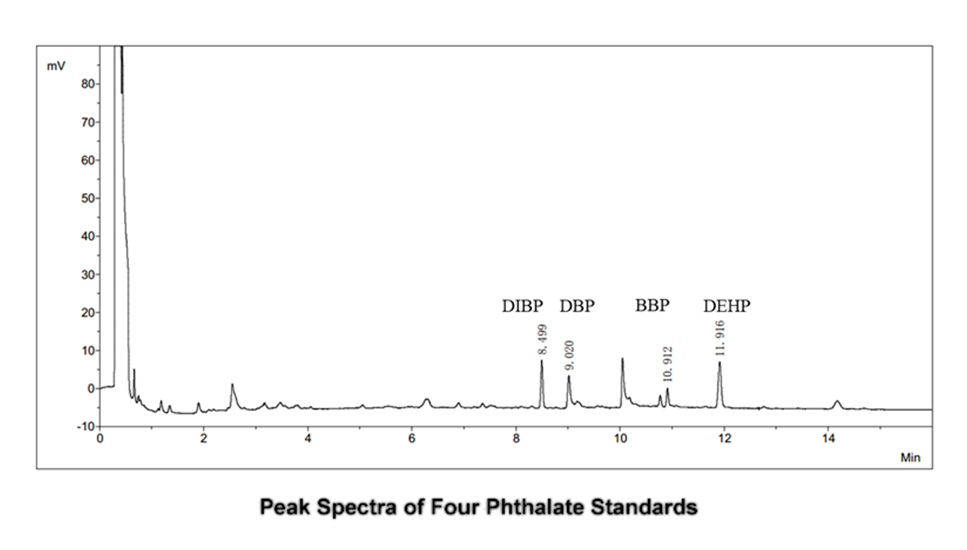

|

Name |

Abbreviation |

Retention Time |

Time Window Band |

|

Diisobutyl Phthalate |

DIBP |

8.524 |

0.05 |

|

Dibutyl Phthalate |

DBP |

9.041 |

0.05 |

|

Butyl Benzyl Phthalate |

BBP |

10.941 |

0.05 |

|

Bis(2-ethylhexyl) Phthalate |

DEHP |

11.949 |

0.05 |

Part 6: Results and Discussions:

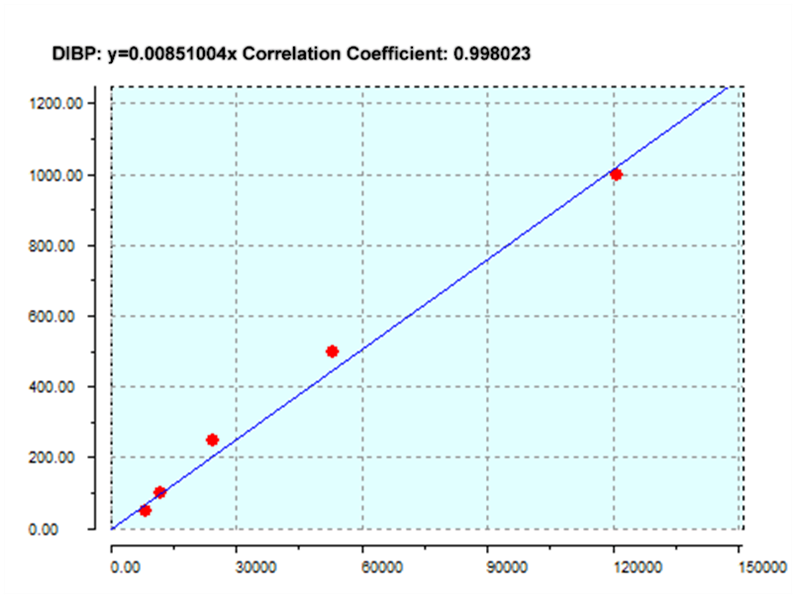

• Standard Curve and Linear Range (Detection Limit)

Prepare DIBP standard solutions with concentrations of 50 ppm, 100 ppm, 250 ppm, 500 ppm, and 1000 ppm. Using the concentration as the abscissa and the peak area of the quantitative component as the ordinate, draw a standard curve. The standard curve and the linear correlation coefficient are as follows.]

The following table is a comparison chart of the peak heights and peak areas of five standard samples with different concentrations:

|

Concentration (ppm) |

Peak Height (pA) |

Peak Area (A) |

|

50 |

2038.7 |

8472.5 |

|

100 |

2829.6 |

12607.7 |

|

250 |

5720.6 |

24674.0 |

|

500 |

12090.8 |

53037.4 |

|

1000 |

24747.2 |

120759.3 |

Note: The lowest detection limit of each component calculated based on the 3-fold signal-to-noise ratio is 25 ppm.

• Repeatability (Precision Experiment)

Repeatability determination was carried out at the concentration of the lowest detection limit, and the results are as follows:

|

RSD% |

||

|

DIBP |

Peak Height |

Peak Area |

|

1 |

944.8 |

3484.2 |

|

2 |

1007.3 |

3638.8 |

|

3 |

903.2 |

3167.9 |

|

4 |

1205.6 |

4227.6 |

|

RSD%=5.24 |

||

Conclusion: For this rapid screening method of phthalates in RoHS 2.0, the lowest detection limit is 25 ppm (the lowest detection limit of PY + GC-MS is 50 ppm), the linear correlation coefficient is greater than 0.998, and the relative standard deviation (RSD%) is 5.24. It fully meets the requirements for screening enterprise materials.

Part 7: Typical Application Cases

The EDX-4 RoHS 2.0 testing system is widely applied in industries such as toys, electronics, food, packaging materials, plastics for medical devices, rubber, adhesives, cellulose, resins, cables, etc.

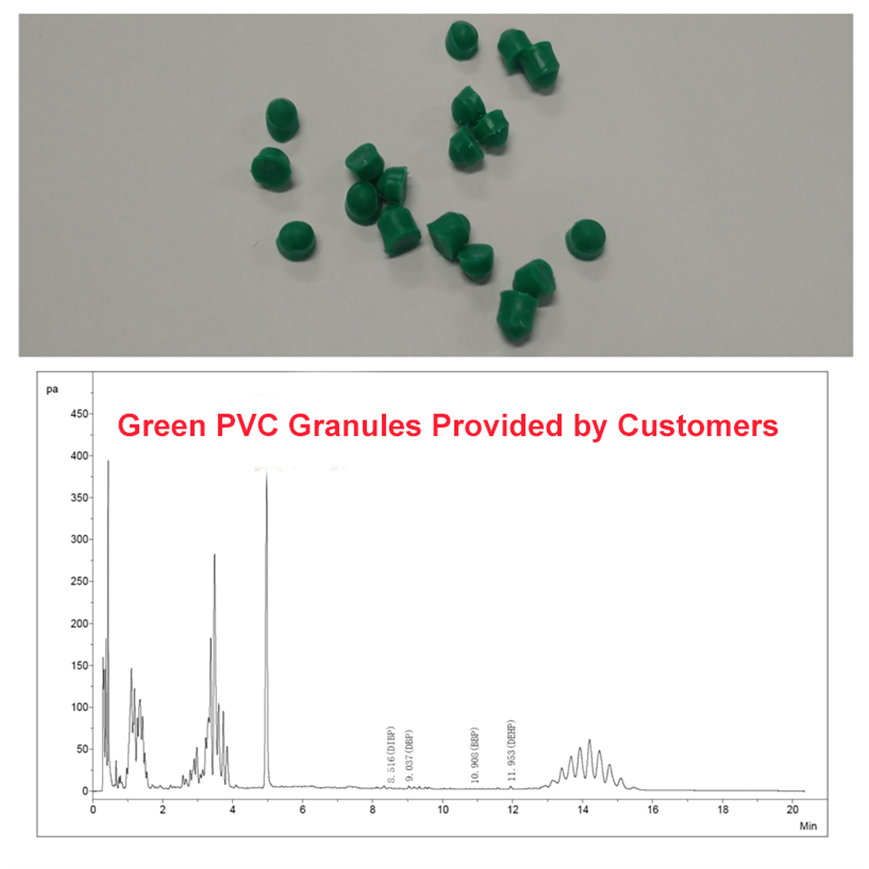

Experimental Case 1: The raw materials of the plastic shells of the headphones manufactured on behalf of an international well-known brand by a certain headphone manufacturer need to be tested for the screening of four phthalates in RoHS.

• Instrument: LISUN EDX-4 RoHS 2.0 testing system

• Sampling method: Direct solid sampling;

• Detection item: Detect whether the four phthalates in RoHS exceed the standard in the virgin PVC green granules.

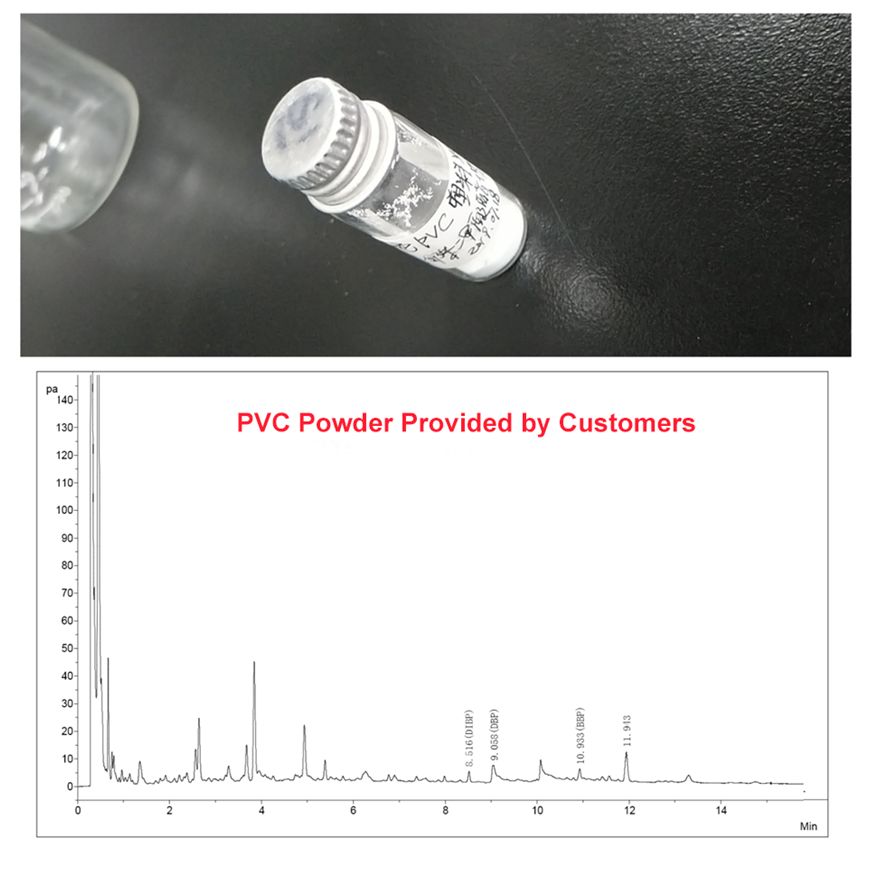

Experimental Case 2: A manufacturer of mobile phone chargers exporting to Europe needs to conduct the screening of four phthalates in RoHS.

• Instrument: LISUN EDX-4 RoHS 2.0 testing system

• Sampling method: Direct solid sampling;

• Detection item: Detection of phthalates of type Ia in the white PVC plastic powder.

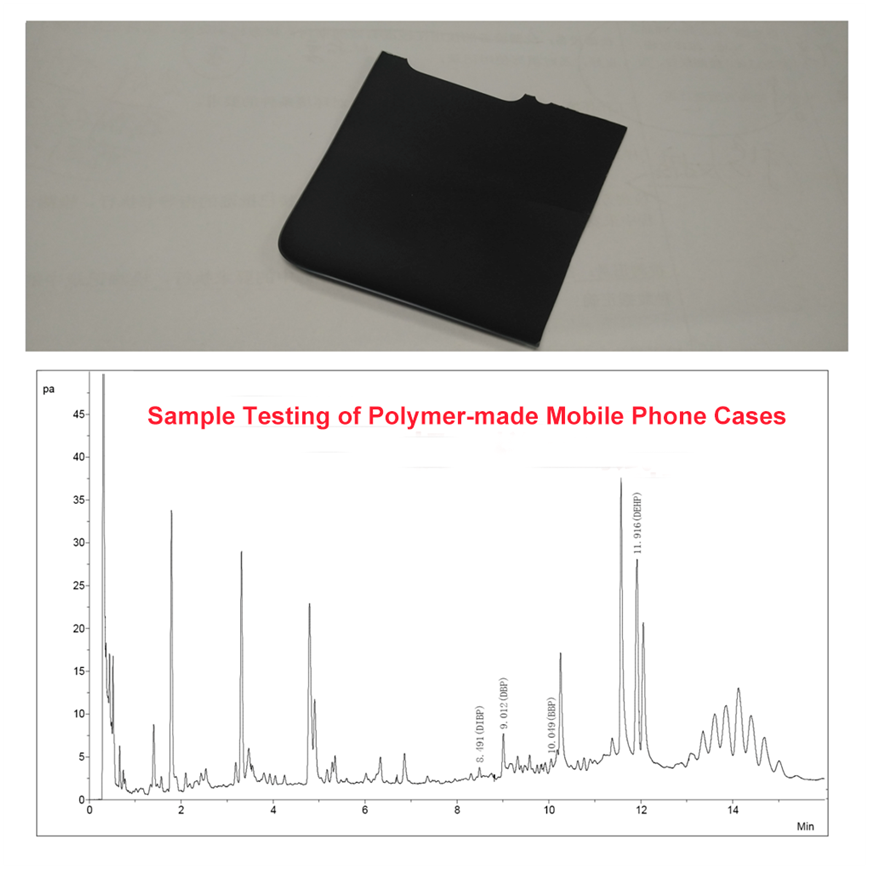

Experimental Case 3: A well-known brand mobile phone manufacturer needs to conduct the screening of four phthalates in RoHS for the polymer materials of the mobile phone backplates exported to Europe.

• Instrument: LISUN EDX-4 RoHS 2.0 testing system

• Sampling method: Direct solid sampling;

• Detection item: Detection of 22 phthalates in the polymer material of the mobile phone back cover.

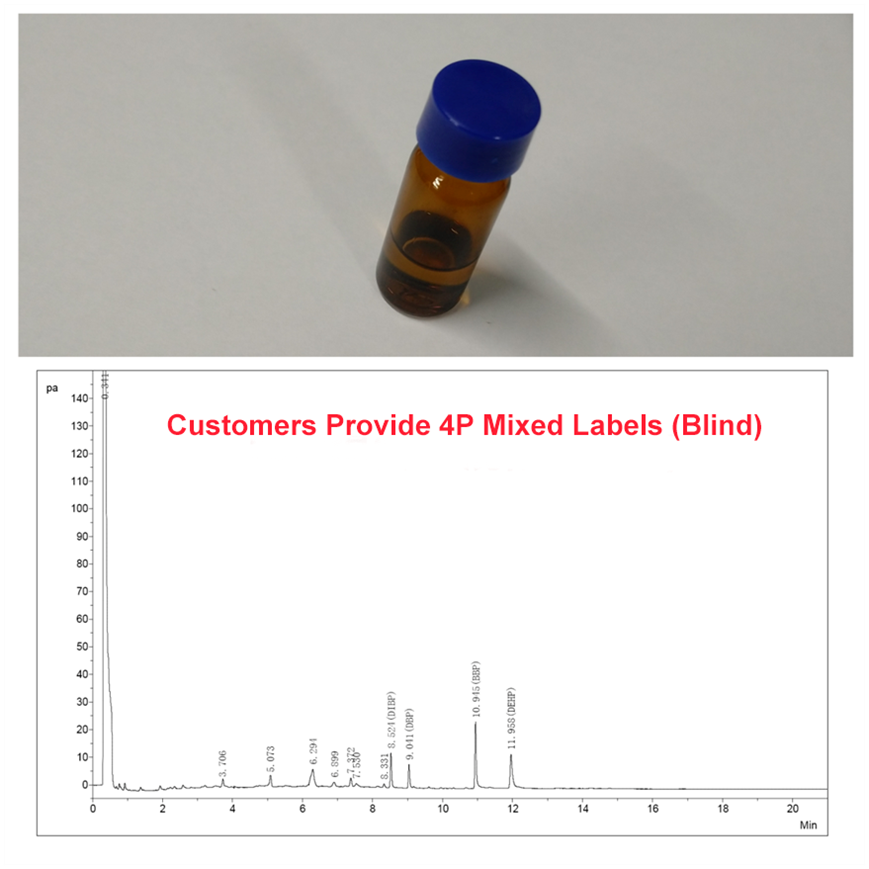

Experimental Case 4: The customer-prepared mixed standard sample (containing four phthalates, blind sample) is used for the screening of four phthalates in RoHS.

• Instrument: LISUN EDX-4 RoHS 2.0 testing system

• Sampling method: Direct liquid sampling;

• Detection item: Detect the contents of four phthalates in the blind sample (mixed standard).