Product No: LVD-AT01

The LVD-AT10 Electrodynamic Vibration Test System (iLac-MRA/ISO 17025 CNAS Certified) with several advantages, including a wide frequency range, easy operation, and convenient maintenance. With a selectable force range from 1 kN to 60 kN, it is widely used in various mechanical environment tests in the fields of aviation, aerospace, maritime, rail transit, and new energy.

Vibration is a form of motion in which an object oscillates around its equilibrium position. It is typically characterized by physical quantities (such as displacement, velocity, and acceleration) as functions of time, representing the vibration’s time history. Vibration can be categorized by its cause into free vibration, forced vibration, and self-excited vibration; by its pattern into sinusoidal vibration and random vibration; and by its degrees of freedom into single-degree-of-freedom vibration and multi-degree-of-freedom vibration.

An Electrodynamic Vibration Test System utilizes the principle of electromagnetic induction to convert electrical energy into mechanical energy using a transducer. The basic operating principle is based on Ampere’s law: a current-carrying conductor experiences an electromagnetic force when placed in a magnetic field. The electromagnetic force acting on the current-carrying conductor is proportional to the current in the conductor, the effective length of the conductor in the magnetic field, and the magnetic flux density of the magnetic field. The direction of the electromagnetic force is determined by the left-hand rule. When the energized conductor is subjected to resistance in a constant magnetic field, the varying force on the moving coil generates vibration. The moving coil winding of the Electrodynamic Vibration Test System is located in a high magnetic flux density gap. The vibration signal is generated from a signal generator or vibration controller and amplified by a power amplifier before being transmitted to the moving coil winding, producing the desired vibration waveform in the Electrodynamic Vibration Test System.

LVD-AT10 Electrodynamic Vibration Generator System Test Principle

The applications of the electrodynamic vibration test system are extensive:

• It can perform vibration fatigue tests on products, components, and materials.

• Environmental routine vibration tests: including detecting the resonance frequency of products or components and simulating the vibration experienced by test pieces or components in actual use to enhance their reliability.

• Dynamic characteristic tests: measuring the physical effects (such as stress changes) of vibration on components or materials to provide reliable data for design purposes.

• Calibration of various types of sensors (e.g., accelerometers, velocimeters, displacement sensors).

The main components of the electrodynamic vibration table test system are:

• Vibration Table Host: excitation source to generates vibration.

• Power Amplifier: Amplifies the voltage signal provided by the controller to drive the vibration table.

• Cooling System: Provides forced cooling to the vibration table.

• Horizontal Slide Vibration Table and Vertical Expansion Vibration Table: to do X/Y/Z axis vibration.

• Control System (Controller, PC with software): Controls the vibration test parameters, allowing the vibration table to follow the predefined vibration profiles.

• Fixtures (optional): Designed according to the test object or customer requirements, used for mounting and securing the test object.

• High and low temperature acceleration sensor with 10m signal line (built-in)

Standard (Full-Compliance CNAS Certificated):

IEC 60068-2-6 “Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)”

JJG189-97 “Electrodynamic Vibration Generator System for LED and Electrical Product Test”

ISO 2247 “Packaging – Complete, filled transport packages and unit loads – Vibration tests at fixed low frequency”

ISO 13355 “Packaging – Complete, filled transport packages and unit loads – Vertical random vibration”

ASTM D999 “Standard Test Methods forVibration Testing of Shipping Containers”

ASTM D4728 “Standard Test Method for Random Vibration Testing of Shipping Containers”

ASTM D3580 “Standard Test Methods for Vibration (Vertical Linear Motion) Test of Products”

IEC 60598-1:2020 “Luminaires – Part 1: General requirements and tests” Clause 4.20

Specification:

| LISUN Model | LVD-AT01 | LVD-AT10 | LVD-AT30 | LVD-AT60 |

| Max. Object to be measured (kg) | 100 | 300 | 500 | 800 |

| Rated thrust (kN) (sine) | 1 | 10 | 30 | 60 |

| Rated thrust (kN) (random) | 1 | 10 | 30 | 60 |

| Rated thrust (kN) (impact) | 2 | 20 | 60 | 120 |

| Rated sinusoidal acceleration (m/s²) | 650 | 980 | 980 | 1127 |

| Rated random acceleration (m/s²) | 650 | 784 | 980 | 784 |

| Vertical platform weight (kg) | 175 | 900 | 1750 | 3500 |

| Vibration table size (mm) L*W*H | 400*365*470 | 930*720*760 | 1180*780*1090 | 1400*1010*1400 |

| Frequency range (Hz) | 5~6000 | 5~4000 | 5~3000 | 5~2700 |

| Rated displacement p-p (mm) | 25 | 51 | 51 | 76 |

| Rated speed (m/s) | 1.6 | 2 | 2 | 2 |

| Mass of moving parts (kg) | 1.5 | 10 | 25 | 53 |

| Moving coil diameter (mm) | Φ120 | Φ240 | Φ340 | Φ445 |

| Magnetic flux leakage (mT) | ≤1 | ≤1 | ≤1 | ≤1 |

| Moving coil fixing screw | Φ90-6*M8 | Φ100-8*M10 | Φ150-8*M10 | Φ200-8*M12 |

| Φ200-8*M10 | Φ300-8*M10 | Φ400-8*M12 | ||

| System Power Requirements (kVA) | 3 | 21 | 46 | 96 |

| Power Amplifier Specifications | ||||

| Rated output power (kVA) | 1 | 10 | 30 | 60 |

| System protection function | With multiple performance protection | |||

| Signal-to-noise ratio (dB) | ≥65 | ≥65 | ≥65 | ≥65 |

| Weight (kg) | 30 | 550 | 590 | 640 |

| Overall dimensions (mm) L*W*H | 440*580*125 | 550*850*1770 | 550*850*1770 | 550*850*1990 |

| Cooling fan specifications | ||||

| Fan power (kW) | 0.75 | 4 | 7.5 | 22 |

| Fan flow rate (m³/s) | 0.18 | 0.5 | 0.8 | 1.3 |

| Overall dimensions (mm) L*W*H | 380*500*1010 | 800*530*1270 | 930*640*1440 | 1200*900*1900 |

| Fan speed (r/min) | 2900 | 2900 | 2900 | 2900 |

| Weight (kg) | 40 | 120 | 180 | 460 |

| Wind pressure (Pa) | 1500 | 5000 | 2600 | 12000 |

| High & Low Temperature Humidity Chamber (Optional, please refer to the below image) | ||||

| LISUN Model | GDJS-LVD-490* | GDJS-LVD-1500* | GDJS-LVD-2200* | GDJS-LVD-3800* |

| Workroom Size (mm) | 800*765*800 | 1330*1120*1000 | 1580*1180*1200 | 1800*1410*1500 |

| Temperature Range | A: -20℃~150℃ C: -60℃~150℃ | |||

| Fluctuation/Evenness | ±0.5℃/±2℃ | |||

| Temperature Rise Speed | 1.0℃~3.0℃/min | |||

| Temperature Fall Speed | 0.7℃~1.0℃/min | |||

| Humidity Range | 20%~98%RH | |||

| Humidity Deviation | -2%~-3% | |||

High & Low Temperature, Humidity and Vibration Test Chamber (Option)

Notes:

1. Electrodynamic Vibration Generator System with larger vibration table sizes or greater thrust can be customized according to customer requirements.

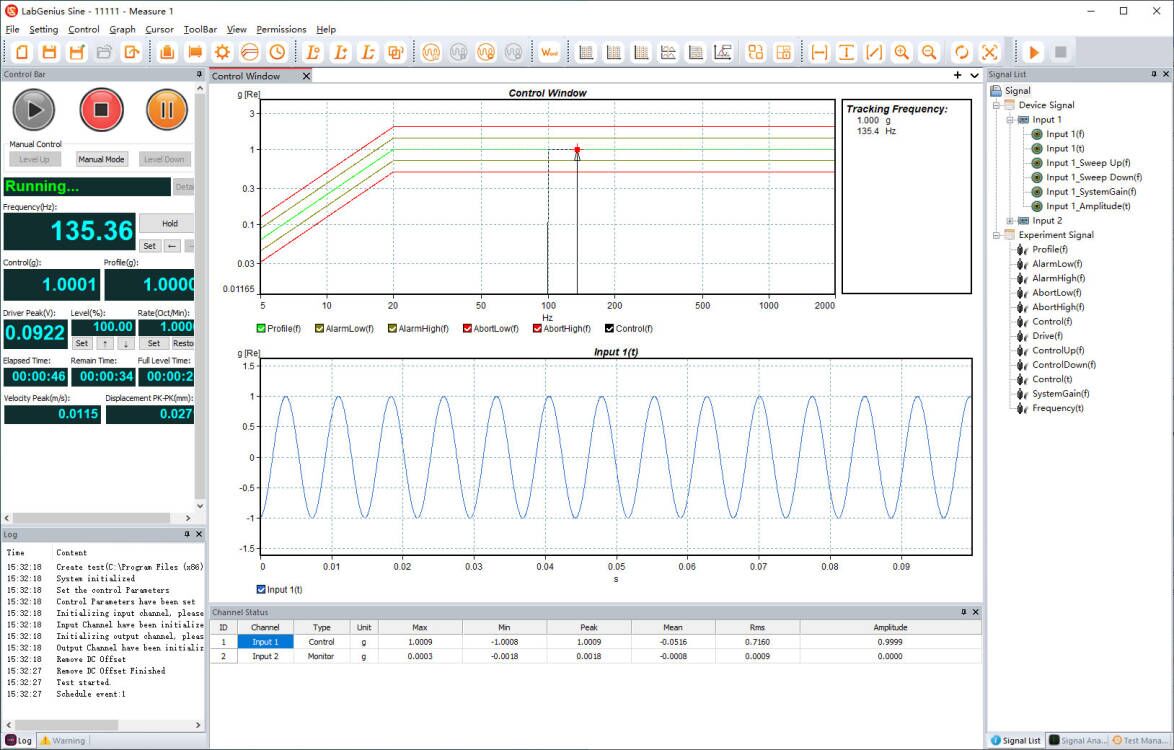

LVD-AT10 Software Interface – Sine Control

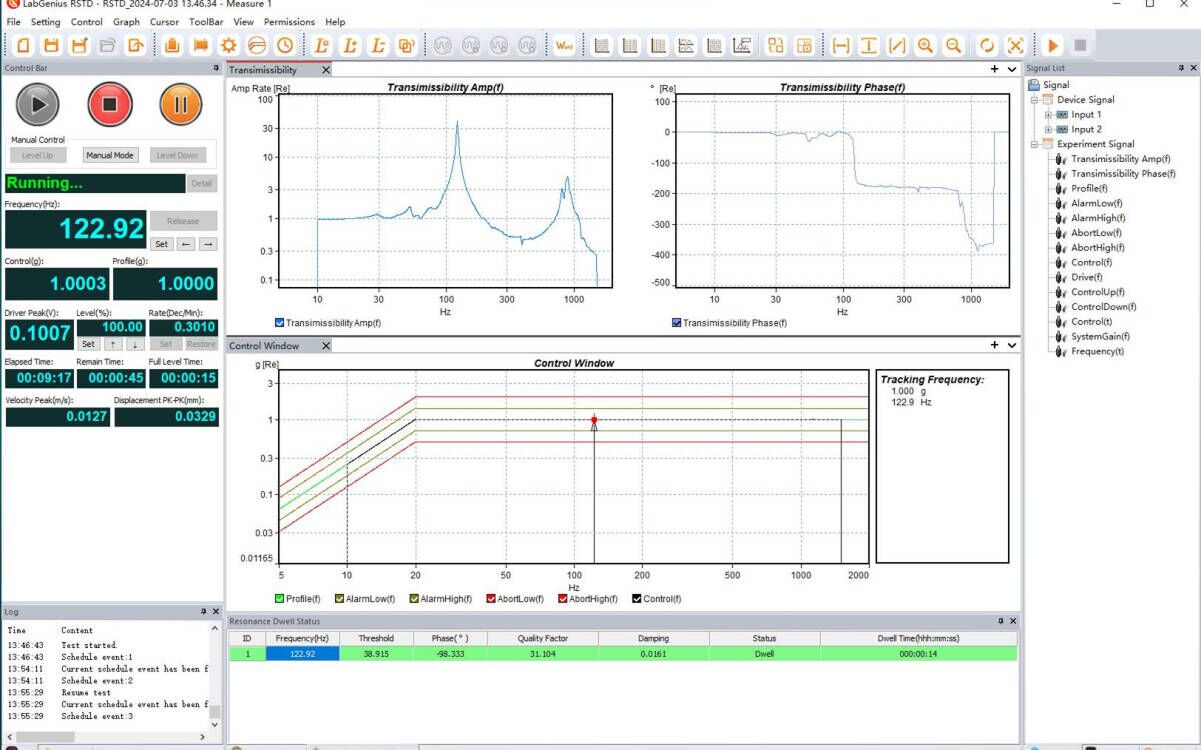

LVD-AT10 Software Interface – Resonance Search and Dwell

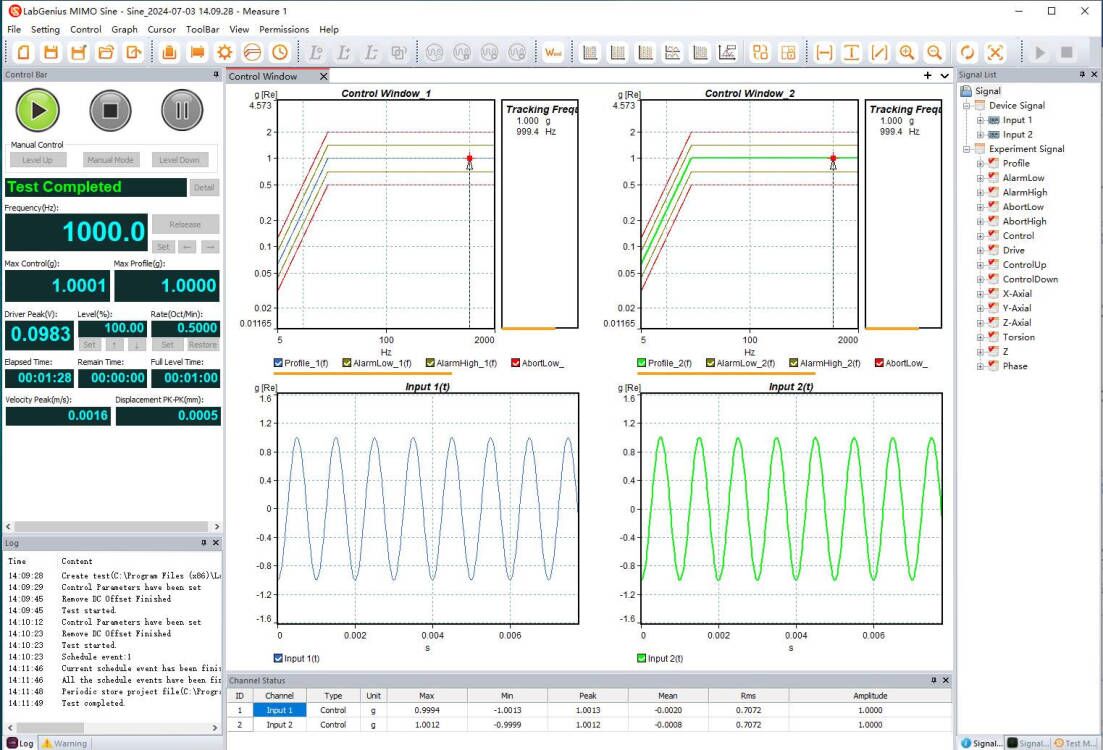

LVD-AT10 Software Interface

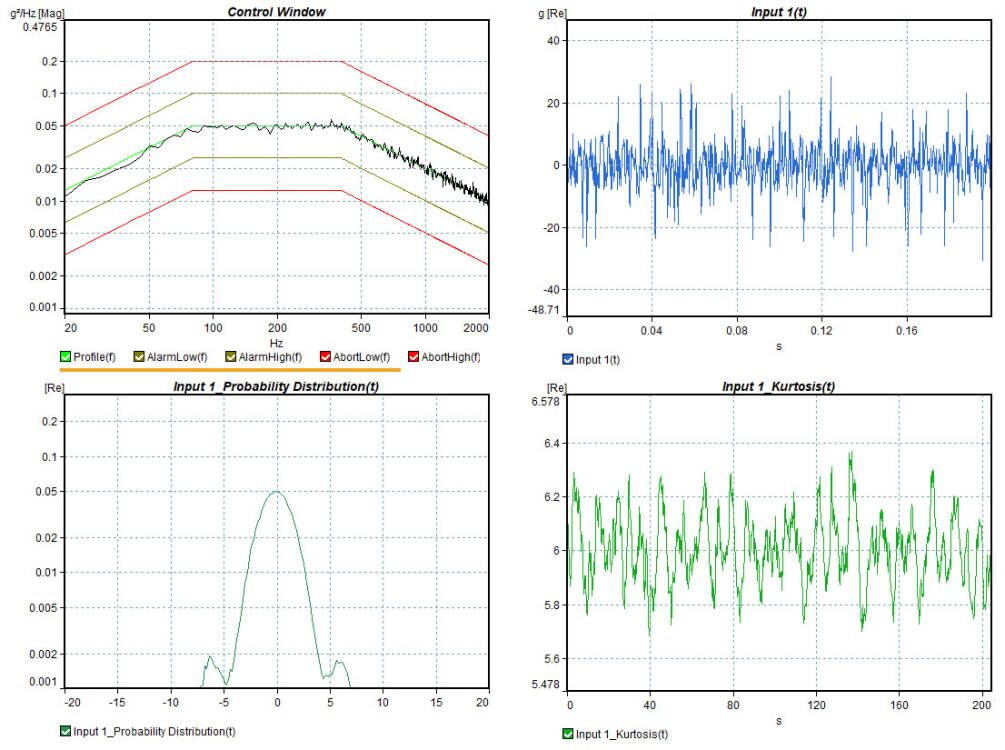

LVD-AT10 Software Interface – Ultra-Gauss Control