Product No: JL-IWJ-010

JL-IWJ-010 Ice Water Impact Immersion Test Chamber is a composite test chamber for ice water splash test and ice water immersion test. It can be used for splash or immersion test alone, simulating ice water splashing or immersion on heating system or components when driving on wet roads in winter. The failure mode is mechanical cracking of materials or sealing failure caused by different temperature expansion coefficients. It is a reliability test equipment for various raw materials and devices such as electronics, electrical engineering, electrical appliances, plastics, etc. to conduct cold resistance, heat resistance, ice water splash resistance, ice water immersion resistance and quality control engineering.

Standard:

• ISO16750-4 Road Vehicles- Environmental Conditions and Testing for Electrical and Electronic Equipment – Part 4: Climatic Loads|5.4 Ice Water Shock Test

• VOLKSWAGEN|VW 80000 Electric and Electronic Components in Motor Vehicles up to 3.5 t General Requirements, Test Conditions, and Tests|11.12 K-12 Thermal Shock with Splash Water|11.13 K-13 Thermal Shock Immersion

• MBN LV 124-2 Electric and Electronic Components in Motor Vehicles up to 3,5t – General Requirements, Test Conditions and Tests|Part 2: Environmental Requirements → 14.12 K-12 Thermal Shock With Splash Water|14.13 K-13 Thermal Shock Immersion

• GB/T 28046.4 Road Vehicles – Environmental Conditions and Testing for Electrical and Electronic Equipment – Part 4: Climatic Loads (ISO 16750-4:2006, MOD)

Specififation:

• Applicable to the product of the ice -resistant water splash test and the ice water immersion test

• The inner box is made of SUS316#stainless steel plate to ensure that it is not rust for a long time

• The high -temperature system uses a long -axis fan motor, which is resistant to high and low temperature 316 stainless steel multi -wing leaf wheels to achieve the intensity -to -blooming circulation, so that the temperature in the laboratory is uniform and keeps stable

• The testhole (100mm diameter) is installed on the left side of the device.

• The control system uses a 7 -inch touch screen+Panasonic PLC control to control the temperature in the chamber, the temperature of the water tank, the flow and the pump and the test time in the chamber.

• The refrigeration system adopts a fully closed French Taikang compressor.

• Ice water splash test: spraying the peak is fixed on the right side of the test chamber; adjust the water spray distance through the sample movement.

• Flow Sensor: Use the flow sensor to control the flow of the ice water splash test. The signal of the flow sensor will be fed back to the PLC, and the automatic constant current controls it through the PID.

• Set the automatic high and low water level of the water tank. The high water level is used to do ice water immersion test. The bottom water level is used to do ice water splash test to reduce the amount of dust use

• The ice water splash test and the water tank flushing circulation test uses custom cycle pumps to ensure the stable flow and water temperature.

• The ice water temperature control device adopts water circulation cooling method to ensure the uniformity of water temperature and mixed water

| Inner Dimensions | 1000*1000*1000 (mm) (W*D*H) |

| External Dimensions | 1600*1950*2710 (mm) W*D*H |

| Basket Dimensions | 500×500×500mm(W*D*H) |

| Immersed water tank size | 600*600*600(W*D*H) |

| Nozzle quantity | 1 slot nozzle |

| Spraying position | On the right side of the inner box |

| Spirit and sample distance | 325±25mm( Can be adjusted manually) |

| Basket load | 50KG |

| Immersion water tank | About 200L (stirring in circulating water, the bottom slope, easy to clean and drain) |

| High temperature chamber temperature range | RT+10℃~150℃( PLC settings) |

| Heating rate | RT+10℃~150℃≤45min |

| Water temperature control range | (0~+4)℃(Control by PLC) |

| Cooling rate | 25℃~2℃≤60min |

| Water spray | (3~4)L/3S(PLC setting) |

| Test liquid | Remove water or+5%NACL+3%Arizona fine dust |

| Spray time per cycle (30 minutes) | 3s, interval time: interval time: 29m57s (PLC setting) |

| Number of Cycles | 100(PLC setting) |

| Transfer duration | ≤20S(PLC Setting) |

| Immersion Time | 1~99 min(PLC Setting) |

| Number of Immersion time | 1~99 (PLC Setting) |

| The temperature uniformity of the ice water in the chamber | ±0.5℃ |

| Automatic cleaning function | After the test is completed, automatically clean the pipeline and the inner chamber (need to be used to hold the spray gun) |

| Water temperature cooling method | Pipe circulation water flow cooling |

| Dust mixed method | Pipe circulation water flow mixing |

| Spray nozzle | Folding and removing crack nozzle (spray can be disassembled and cleaned) |

| How to use the test liquid | Recycle |

| Sample carrier table | Lifting |

| Power Supply | 380V/15KW/50Hz, Three -phase and five -line system |

| Safety protection function | Leakage protection, water deficiency protection, short circuit protection, phase sequence protection, heat overload protection |

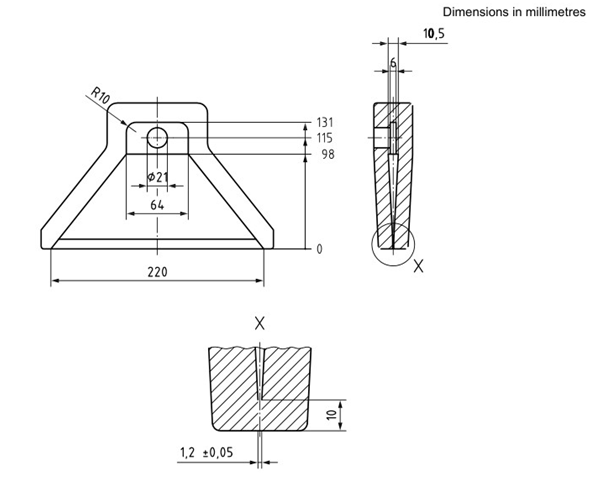

Figure 4 Jet

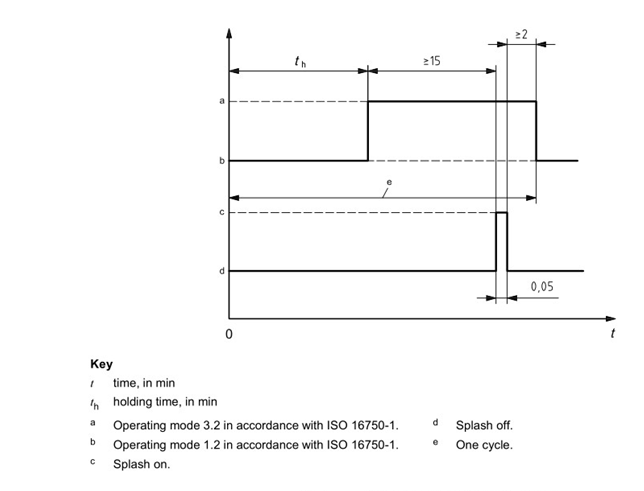

Figure 5 Test Cycle for Splash water test

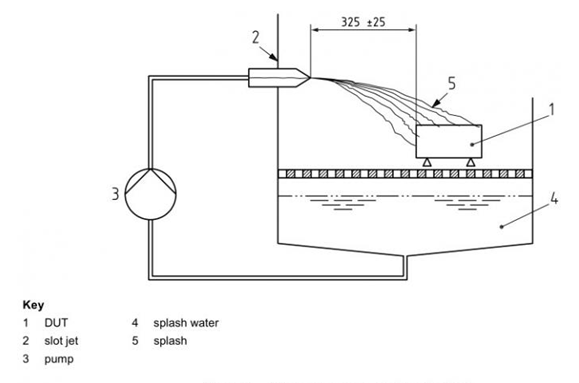

Figure 6 Test set for Splash water test