Product No: UL-JLX1

The UL Water Spray Test Device is fully meet UL 60507-ENGL 1999 of Figures 38.1 and 38.2 , ANSI Z21.58 Clause 5.23.1 Figures 12 and 13 , and the CSA 4.3-2004 standard. It complies with UL 1598 standard of Clause 19.17 Figures 19.17.1 and 19.17.2 , as well as the UL 153, UL 154B, UL 1703, UL 8750, UL 1741, UL 514B, UL 1278, and UL 1571 standards.

The equipment program includes standard test options, allowing users to select the required standard test items and conduct tests without additional setup. Additionally, it features custom test options, enabling users to set test parameters independently to accommodate the testing of different samples.

Structure:

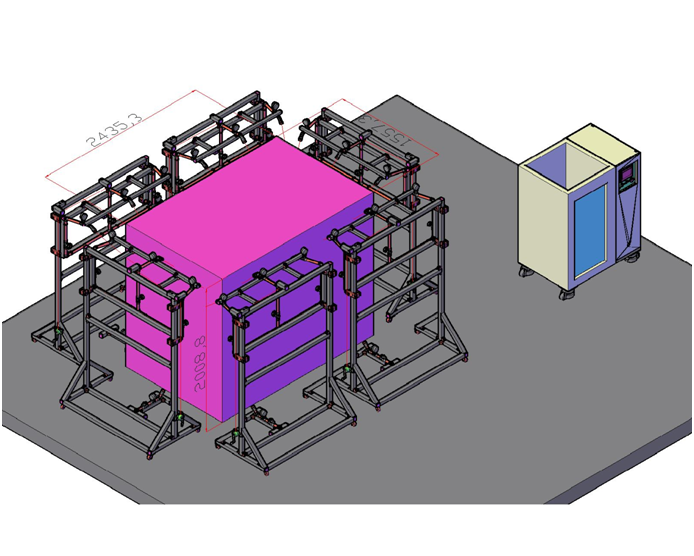

• This system consists of a water supply control box (with a water tank) and six UL spray devices, designed for a comprehensive waterproof testing chamber.

• The water supply control box and spray devices are placed separately. After positioning the sample, the operator can start the test from the control panel, ensuring they remain at a safe distance from the test apparatus to better guarantee personal safety.

• Water hoses distribute water from the supply system to each spray device, ensuring the setup is orderly and aesthetically pleasing.

Specification:

• Suitable for conducting UL rain and 45° spray tests on products.

• Each unit consists of two parts: the UL rain test device (three UL nozzles on the top) and the spray test device (one UL nozzle on the bottom).

• The nozzle frame is made of molded aluminum material, providing stable structure and easy cleaning.

• The nozzle frame is movable, with free vertical adjustment via a hand-cranked stainless steel wheel mechanism.

• The base of the frame is equipped with universal casters with brakes, facilitating easy movement and secure positioning.

• Number of frames: 6 sets.

• Adjustable nozzle height range: 1000~2000mm

• Nozzle height adjustment method: manual

• Number of nozzles: 4 per set, 6 sets total

• Environmental conditions: temperature 5℃ to 35℃, relative humidity ≤85%, power supply 380V, 5KVA

• Water spray convergence point height from ground: 0-1000mm

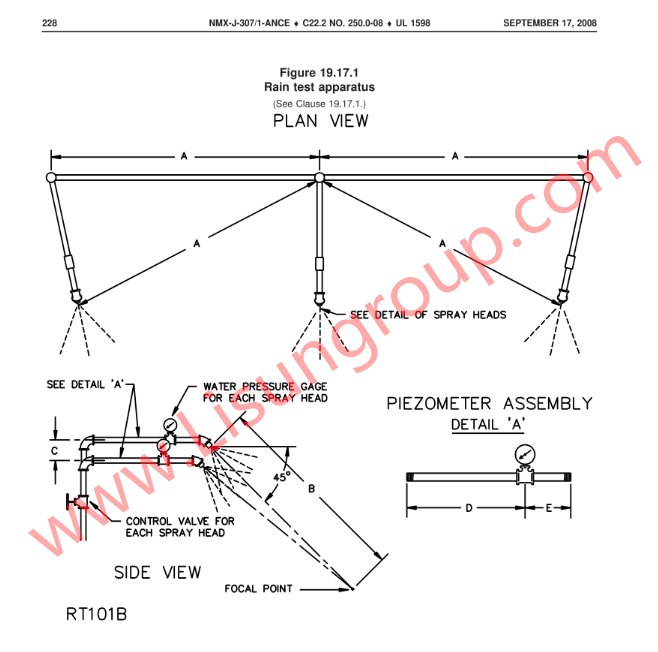

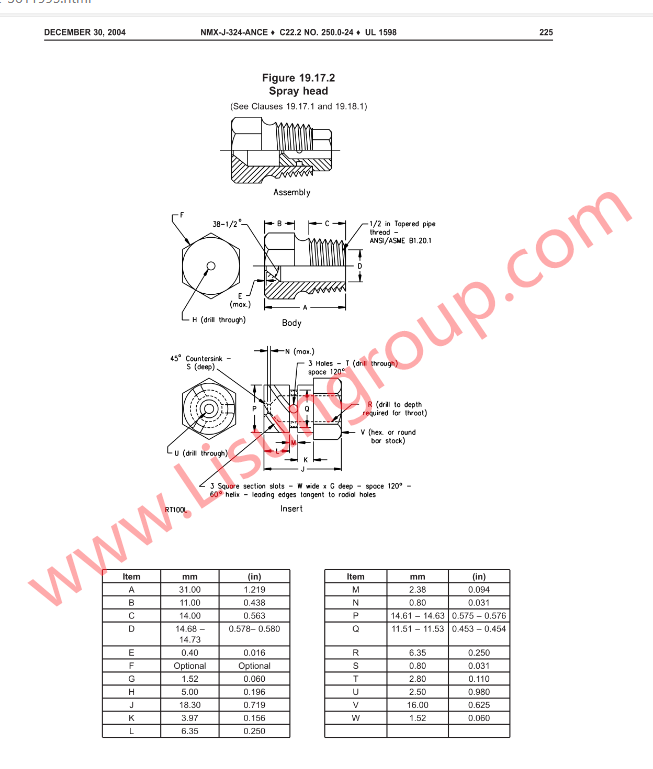

• Distribution of upper nozzles (strictly according to standard) as per Figures 19.17.1 and 19.17.2

• Lower nozzle spray angle: 45° (horizontal direction)

• Pressure of each nozzle: 34.5 Kpa

• Number of pressure gauges: 4 per set, 6 sets total

• Pressure gauge brand: Hongqi

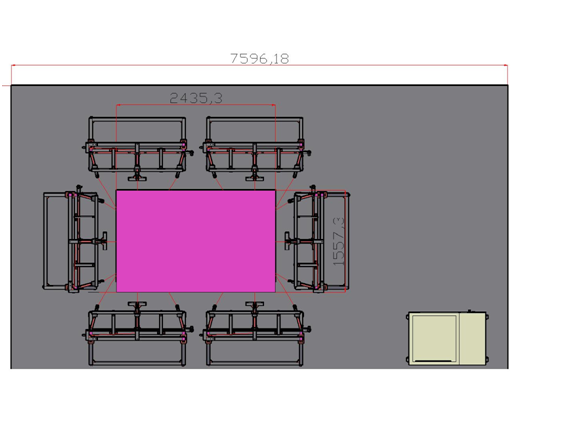

• Maximum allowable test sample size: 2435.3*1557.3*2008.8mm (W*D*H)

• Reference diagram for the distribution of the frames

Figure 19.17.1

Figure 19.17.2

Diagram for the distribution of the frames

Diagram of UL water spray test device

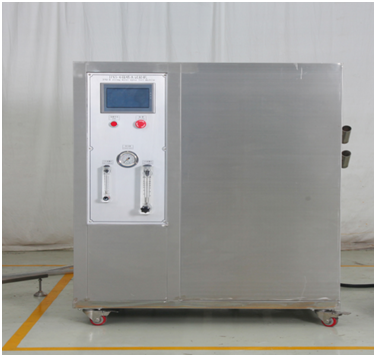

Water Supply Control Chamber (with Water Tank):

• Control functions: spray time control

• Control screen: MCGS 7-inch

• PLC controller: Panasonic(Japan)

• Electrical components: all imported brands including LS, Panasonic, Omron, and Anly

• Protection functions: leakage protection, overload protection, short circuit protection

• Water tank capacity: approximately 500L

• Water tank material: SUS304 stainless steel

• Water supply outlets: 12 channels (one for each frame, totaling 6 channels; one for each 45° nozzle, totaling 6 channels)

• Water supply piping: high-quality hoses used for water supply are distributed to each device according to on-site layout, with each device controlled by a solenoid valve

• Internal piping material of the water supply machine: SUS304 stainless steel pipes

Water Supply Control Chamber

Tags:UL-JLX1